Page 853 - 21-036 APPLITEC catalogue.indb

P. 853

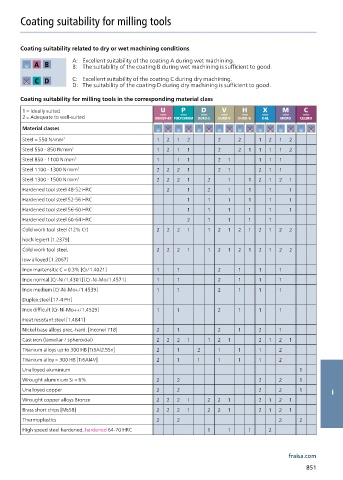

Coating suitability for milling tools

Coating suitability related to dry or wet machining conditions

A: Excellent suitability of the coating A during wet machining.

A B B: The suitability of the coating B during wet machining is sufficient to good.

C D C: Excellent suitability of the coating C during dry machining.

D: The suitability of the coating D during dry machining is sufficient to good.

Coating suitability for milling tools in the corresponding material class

1 = Ideally suited U P D V H X M C

2 = Adequate to well-suited UNICUT-4X POLYCHROM DURO-S DURO-V DURO-Si X-AL MICRO CELERO

Material classes

Steel < 550 N/mm 2 1 2 1 2 2 2 1 2 1 2

Steel 550 - 850 N/mm 2 1 2 1 1 2 2 1 1 1 1 2

Steel 850 - 1100 N/mm 2 1 1 1 2 1 1 1 1

Steel 1100 - 1300 N/mm 2 2 2 2 1 2 1 2 1 1

Steel 1300 - 1500 N/mm 2 2 2 2 1 2 1 1 2 1 2 1

Hardened tool steel 48-52 HRC 2 1 2 1 1 1 1

Hardened tool steel 52-56 HRC 1 1 1 1 1 1

Hardened tool steel 56-60 HRC 1 1 1 1 1 1

Hardened tool steel 60-64 HRC 2 1 1 1 1

Cold work tool steel (12% Cr) 2 2 2 1 1 2 1 2 1 2 1 2 2

hoch legiert [1.2379]

Cold work tool steel, 2 2 2 1 1 2 1 2 1 2 1 2 2

low alloyed [1.2067]

Inox martensitic C < 0.3% [Cr/1.4021] 1 1 2 1 1 1

Inox normal [Cr-Ni/1.4301] [Cr-Ni-Mo/1.4571] 1 1 2 1 1 1

Inox medium [Cr-Ni-Mo+/1.4539] 1 1 2 1 1 1

Duplex steel [17-4 PH]

Inox difficult [Cr-Ni-Mo++/1.4529] 1 1 2 1 1 1

Heat resistant steel [1.4841]

Nickel base alloys prec.-hard. [Inconel 718] 2 1 2 1 2 1

Cast iron (lamellar / spheroidal) 2 2 2 1 1 2 1 2 1 2 1

Titanium alloys up to 300 HB [Ti5Al2.5Sn] 2 1 2 1 1 1 2

Titanium alloy > 300 HB [Ti6Al4V] 2 1 1 1 1 1 2

Unalloyed aluminium 1

Wrought aluminium Si < 6% 2 2 2 2 1

Unalloyed copper 2 2 2 2 1

i

Wrought copper alloys Bronze 2 2 2 1 2 2 1 2 1 2 1

Brass short chips [Ms58] 2 2 2 1 2 2 1 2 1 2 1

Thermoplastics 2 2 2 2

High speed steel hardened, hardened 64-70 HRC 1 1 1 2

fraisa.com

851