Page 351 - Carbide drills I Thread cutting tools 2023

P. 351

Technical notes regarding use of drilling tools

Lubrication and coolant pressure

Basically, when drilling work with lubricant. The goal is more efficient chip removal and heat reduction. Hardened

steel or abrasive materials can be cooled by using air or treated with MQL (minimal quantity lubrication).

If the coolant is applied externally, ensure the correct positioning of the coolant jet. This should be in the flute

(directed parallel to the helix angle) and the entrance to the hole.

The use of internal cooling (internal coolant supply) can increase tool life. It is necessary, depending on the tool

diameter, to apply a minimum coolant pressure.

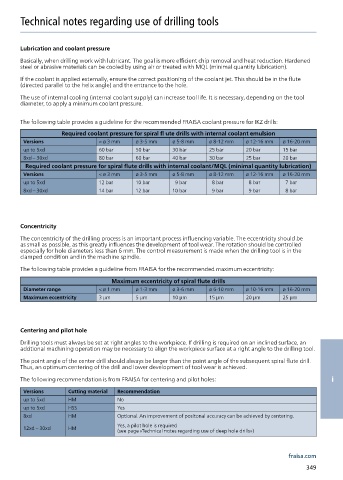

The following table provides a guideline for the recommended FRAISA coolant pressure for IKZ drills:

Required coolant pressure for spiral fl ute drills with internal coolant emulsion

Versions < ø 3 mm ø 3-5 mm ø 5-8 mm ø 8-12 mm ø 12-16 mm ø 16-20 mm

up to 5xd 60 bar 50 bar 30 bar 25 bar 20 bar 15 bar

8xd – 30xd 80 bar 60 bar 40 bar 30 bar 25 bar 20 bar

Required coolant pressure for spiral flute drills with internal coolant/MQL (minimal quantity lubrication)

Versions < ø 3 mm ø 3-5 mm ø 5-8 mm ø 8-12 mm ø 12-16 mm ø 16-20 mm

up to 5xd 12 bar 10 bar 9 bar 8 bar 8 bar 7 bar

8xd – 30xd 14 bar 12 bar 10 bar 9 bar 9 bar 8 bar

Concentricity

The concentricity of the drilling process is an important process influencing variable. The eccentricity should be

as small as possible, as this greatly influences the development of tool wear. The rotation should be controlled

especially for hole diameters less than 6 mm. The control measurement is made when the drilling tool is in the

clamped condition and in the machine spindle.

The following table provides a guideline from FRAISA for the recommended maximum eccentricity:

Maximum eccentricity of spiral flute drills

Diameter range < ø 1 mm ø 1-3 mm ø 3-6 mm ø 6-10 mm ø 10-16 mm ø 16-20 mm

Maximum eccentricity 3 µm 5 µm 10 µm 15 µm 20 µm 25 µm

Centering and pilot hole

Drilling tools must always be set at right angles to the workpiece. If drilling is required on an inclined surface, an

addtional machining operation may be necessary to align the workpiece surface at a right angle to the drilling tool.

The point angle of the center drill should always be larger than the point angle of the subsequent spiral flute drill.

Thus, an optimum centering of the drill and lower development of tool wear is achieved.

The following recommendation is from FRAISA for centering and pilot holes: i

Versions Cutting material Recommendation

up to 5xd HM No

up to 5xd HSS Yes

8xd HM Optional. An improvement of positonal accuracy can be achieved by centering.

Yes, a pilot hole is required

12xd – 30xd HM (see page «Technical notes regarding use of deep hole drills»)

fraisa.com

349