Page 474 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 474

USER GUIDE

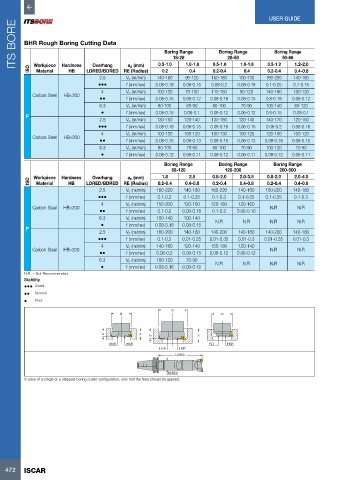

ITS BORE BHR Rough Boring Cutting Data Boring Range Boring Range Boring Range

28-50

18-28

50-68

1.2-2.0

0.5-1.0

1.0-1.8

0.5-1.0

0.5-1.2

ap (mm)

Overhang

Workpiece Hardness

ISO

LDRED/BDRED

HB

0.4

0.2-0.4

0.2-0.4

0.2

0.4-0.8

Material

0.4

2.5 RE (Radius) 140-160 1.0-1.8 150-180 100-130 160-200 140-180

90-120

Vc (m/min)

••• f (mm/rev) 0.08-0.18 0.08-0.15 0.08-0.2 0.08-0.18 0.1-0.25 0.1-0.15

4 Vc (m/min) 100-130 70-100 110-150 90-120 140-180 100-130

Carbon Steel HB<200

•• f (mm/rev) 0.08-0.15 0.06-0.12 0.08-0.18 0.08-0.15 0.8-0.18 0.08-0.12

6.3 Vc (m/min) 80-100 60-90 80-100 70-90 100-140 80-120

• f (mm/rev) 0.08-0.15 0.06-0.1 0.06-0.12 0.06-0.12 0.6-0.15 0.08-0.1

P

2.5 Vc (m/min) 130-150 120-140 130-150 120-140 140-170 120-150

••• f (mm/rev) 0.08-0.18 0.06-0.15 0.08-0.18 0.06-0.15 0.08-0.2 0.08-0.18

4 Vc (m/min) 100-130 100-120 100-130 100-120 120-150 100-120

Carbon Steel HB>200

•• f (mm/rev) 0.08-0.15 0.06-0.13 0.08-0.15 0.06-0.13 0.08-0.18 0.08-0.15

6.3 Vc (m/min) 80-100 70-90 80-100 70-90 100-120 70-90

• f (mm/rev) 0.08-0.12 0.06-0.11 0.08-0.12 0.06-0.11 0.08-0.12 0.06-0.11

Boring Range Boring Range Boring Range

68-120 120-200 200-500

Workpiece Hardness Overhang ap (mm) 1.8 2.5 0.8-2.0 2.0-3.5 0.8-2.0 2.0-4.0

ISO Material HB LDRED/BDRED RE (Radius) 0.2-0.4 0.4-0.8 0.2-0.4 0.4-0.8 0.2-0.4 0.4-0.8

2.5 Vc (m/min) 160-220 140-180 160-220 140-180 160-220 140-180

••• f (mm/rev) 0.1-0.3 0.1-0.25 0.1-0.3 0.1-0.25 0.1-0.35 0.1-0.3

4 Vc (m/min) 150-200 120-160 120-160 120-160

Carbon Steel HB<200 N.R N.R

•• f (mm/rev) 0.1-0.2 0.08-0.18 0.1-0.2 0.08-0.18

6.3 Vc (m/min) 100-140 100-140 N.R N.R N.R N.R

• f (mm/rev) 0.08-0.18 0.08-0.15

P

2.5 Vc (m/min) 160-200 140-180 140-200 140-180 140-200 140-180

••• f (mm/rev) 0.1-0.3 0.01-0.25 0.01-0.35 0.01-0.3 0.01-0.35 0.01-0.3

4 Vc (m/min) 140-160 120-140 150-180 120-140

Carbon Steel HB>200 N.R N.R

•• f (mm/rev) 0.08-0.2 0.08-0.15 0.08-0.12 0.08-0.12

6.3 Vc (m/min) 100-120 70-90 N.R N.R N.R N.R

• f (mm/rev) 0.08-0.16 0.08-0.12

N.R. = Not Recommended

Stability

••• Good

•• Normal

• Poor

Ø

Ø Ø

A A

A1 A

IHSR

IHSR IHSR PLT IHSR

IHCR IHSR

LDRED

BDRED

In case of a single or a stepped boring cutter configuration, only half the feed should be applied.

472 ISCAR