Page 479 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 479

USER GUIDE

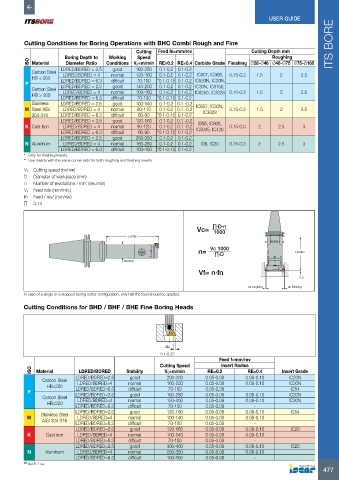

Cutting Conditions for Boring Operations with BHC Combi Rough and Fine ITS BORE

Cutting Feed fn=mm/rev Cutting Depth mm

Boring Depth to Working Speed Roughing

ISO Material Diameter Ratio Conditions Vc=m/min RE=0.2 RE=0.4 Carbide Grade Finishing Ø28-Ø46 Ø46-Ø75 Ø75-Ø160

LDRED/BDRED = 2.5 good 160-250 0.1-0.2 0.1-0.2

Carbon Steel LDRED/BDRED = 4 normal 120-180 0.1-0.2 0.1-0.2 IC807, IC908, 0.15-0.3 1.5 2 2.5

HB < 200

70-100

P LDRED/BDRED = 6.3 difficult 140-200 *0.1-0.15 0.1-0.2 IC520N, IC20N,

LDRED/BDRED = 2.5

0.1-0.2 0.1-0.2

good

IC30N, IC8150,

Carbon Steel LDRED/BDRED = 4 normal 100-160 0.1-0.2 0.1-0.2 IC8250, IC3028 0.15-0.3 1.5 2 2.5

HB > 200

LDRED/BDRED = 6.3 difficult 70-100 *0.1-0.15 0.1-0.2

Stainless LDRED/BDRED = 2.5 good 100-140 0.1-0.2 0.1 -0.2

M Steel AISI LDRED/BDRED = 4 normal 80-110 0.1-0.2 0.1 -0.2 IC807, IC30N, 0.15-0.3 1.5 2 2.5

304-316 LDRED/BDRED = 6.3 difficult 60-90 *0.1-0.15 0.1-0.2 IC3028

LDRED/BDRED = 2.5 good 120-160 0.1-0.2 0.1 -0.2 IB55, IC908,

K Cast Iron LDRED/BDRED = 4 normal 90-120 0.1-0.2 0.1 -0.2 IC5005, IC428 0.15-0.3 2 2.5 3

LDRED/BDRED = 6.3 difficult 60-90 *0.1-0.15 0.1-0.2

LDRED/BDRED = 2.5 good 250-350 0.1-0.2 0.1-0.2

N Aluminum LDRED/BDRED = 4 normal 160-250 0.1-0.2 0.1-0.2 ID5, IC20 0.15-0.3 2 2.5 3

LDRED/BDRED = 6.3 difficult 100-150 *0.1-0.15 0.1-0.2

* Only for finishing Inserts.

** Use inserts with the same corner radii for both roughing and finishing inserts

Vc Cutting speed (m/min)

D Diameter of workpiece (mm)

n Number of revolutions / min' (rev./min)

Vf Feed rate (mm/min.)

fn Feed / rev/ (mm/rev)

∏ 3.14

Vc= ∏·D·n

1000

LDRED

BDRED

n= Vc 1000

.0015 0 .0005 .001 ∏·D LDRED

BDRED

Vf= n·fn

0.2

ap roughing ap finishing

In case of a single or a stepped boring cutter configuration, only half the feed should be applied.

Cutting Conditions for BHD / BHF / BHE Fine Boring Heads

ap

0.1-0.25

Feed f=mm/rev

Cutting Speed Insert Radius

ISO Material LDRED/BDRED Stability Vc=m/min RE=0.2 RE=0.4 Insert Grade

Carbon Steel LDRED/BDRED=2.5 good 200-300 0.05-0.08 0.08-0.10 IC20N

HB<200 LDRED/BDRED=4 normal 160-250 0.05-0.08 0.08-0.10 IC30N

P LDRED/BDRED=6.3 difficult 70-100 0.05-0.08 - IC54

good

Carbon Steel LDRED/BDRED=2.5 normal 160-250 0.05-0.08 0.08-0.10 IC20N

0.05-0.08

0.08-0.10

IC30N

150-200

LDRED/BDRED=4

HB<200

LDRED/BDRED=6.3 difficult 70-100 0.05-0.08 -

LDRED/BDRED=2.5 good 120-160 0.05-0.08 0.08-0.10 IC54

Stainless Steel

M LDRED/BDRED=4 normal 100-140 0.05-0.08 0.08-0.10

AISI 304-316

LDRED/BDRED=6.3 difficult 70-100 0.05-0.08 -

LDRED/BDRED=2.5 good 120-160 0.05-0.08 0.08-0.10 IC20

K Cast Iron LDRED/BDRED=4 normal 100-140 0.05-0.08 0.08-0.10

LDRED/BDRED=6.3 difficult 70-100 0.05-0.08 -

LDRED/BDRED=2.5 good 300-400 0.05-0.08 0.08-0.10 IC20

N Aluminum LDRED/BDRED=4 normal 250-350 0.05-0.08 0.08-0.10

LDRED/BDRED=6.3 difficult 100-150 0.05-0.08 -

(1) ap=0.1 min

477