Page 484 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 484

USER GUIDE

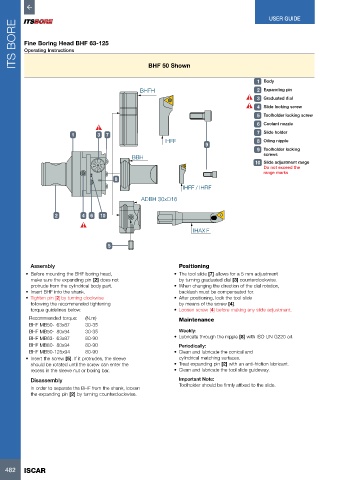

ITS BORE Fine Boring Head BHF 63-125

Operating Instructions

BHF 50 Shown

1 Body

BHFH 2 Expanding pin

3 Graduated dial

4 Slide locking screw

5 Toolholder locking screw

6 Coolant nozzle

1 3 7 7 Slide holder

IHFF 8 Oiling nipple

9

9 Toolholder locking

screws

BBH

0 1 2 10 Slide adjustment range

9 3

Do not exceed the

8

4

7

range marks

5

6

8

IHFF / IHRF

ADBH 30xD16

2 4 6 10

IHAX F

5

Assembly Positioning

• Before mounting the BHF boring head, • The tool slide [7] allows for a 5 mm adjustment

make sure the expanding pin [2] does not by turning graduated dial [3] counterclockwise.

protrude from the cylindrical body part. • When changing the direction of the dial rotation,

• Insert BHF into the shank. backlash must be compensated for.

• Tighten pin [2] by turning clockwise • After positioning, lock the tool slide

following the recommended tightening by means of the screw [4].

torque guidelines below: • Loosen screw [4] before making any slide adjustment.

Recommended torque: (N.m) Maintenance

BHF MB50- 63x87 30-35

BHF MB50- 80x94 30-35 Weekly:

BHF MB63- 63x87 80-90 • Lubricate through the nipple [8] with ISO UN G220 oil.

BHF MB80- 80x94 80-90 Periodically:

BHF MB80-125x94 80-90 • Clean and lubricate the conical and

• Insert the screw [5]. If it protrudes, the sleeve cylindrical matching surfaces.

should be rotated until the screw can enter the • Treat expanding pin [2] with an anti-friction lubricant.

recess in the sleeve nut or boring bar. • Clean and lubricate the tool slide guideway.

Disassembly Important Note:

In order to separate the BHF from the shank, loosen Toolholder should be firmly affixed to the slide.

the expanding pin [2] by turning counterclockwise.

482 ISCAR