Page 823 - 21-036 APPLITEC catalogue.indb

P. 823

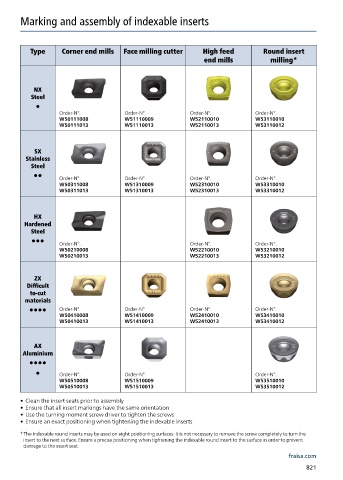

Marking and assembly of indexable inserts

Type Corner end mills Face milling cutter High feed Round insert

end mills milling*

NX

Steel

•

Order-N°. Order-N°. Order-N°. Order-N°.

W50111008 W51110009 W52110010 W53110010

W50111013 W51110013 W52110013 W53110012

SX

Stainless

Steel

•• Order-N°. Order-N°. Order-N°. Order-N°.

W50311008 W51310009 W52310010 W53310010

W50311013 W51310013 W52310013 W53310012

HX

Hardened

Steel

••• Order-N°. Order-N°. Order-N°.

W50210008 W52210010 W53210010

W50210013 W52210013 W53210012

ZX

Difficult

to-cut

materials

•••• Order-N°. Order-N°. Order-N°. Order-N°.

W50410008 W51410009 W52410010 W53410010

W50410013 W51410013 W52410013 W53410012

AX

Aluminium

••••

• Order-N°. Order-N°. Order-N°.

W50510008 W51510009 W53510010

W50510013 W51510013 W53510012

• Clean the insert seats prior to assembly

• Ensure that all insert markings have the same orientation

• Use the turning moment screw driver to tighten the screws

• Ensure an exact positioning when tightening the indexable inserts

* The indexable round inserts may be used on eight positioning surfaces. It is not necessary to remove the screw completely to turn the

insert to the next surface. Ensure a precise positioning when tightening the indexable round insert to the surface in order to prevent

damage to the insert seat.

fraisa.com

821