Page 300 - GARR_TOOL(CATALOG_INT)

P. 300

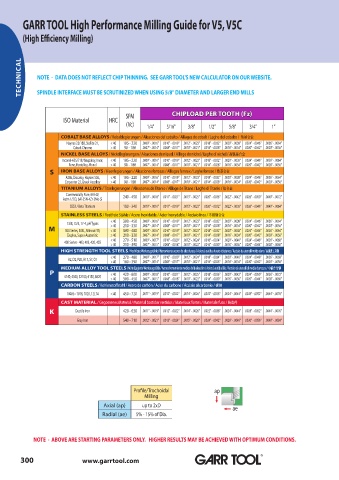

GARR TOOL High Performance Milling Guide for V5, V5C

(High Efficiency Milling)

TECHNICAL NOTE - DATA DOES NOT REFLECT CHIP THINNING. SEE GARR TOOL'S NEW CALCULATOR ON OUR WEBSITE.

SPINDLE INTERFACE MUST BE SCRUTINIZED WHEN USING 5/8" DIAMETER AND LARGER END MILLS

T

TH (Fz)

OO

CHIPL

O

AD PER

SFM CHIPLOAD PER TOOTH (Fz)

ISO Material HRC

(Vc) 1/4" 5/16" 3/8" 1/2" 5/8" 3/4" 1"

o /

/ Kobaltleg

obalt

ierungen / A

lliages de c

obalt

o / A

eghe del c

obalt / L

leaciones del c

COBALT BASE ALLOYS / Kobaltlegierungen / Aleaciones del cobalto / Alliages de cobalt / Leghe del cobalto / 钴基合金

钴基合金

Haynes 25/188, Stellite 21, < 40 105 - 220 .0009" - .0016" .0010" - .0019" .0012" - .0023" .0018" - .0032" .0020" - .0038" .0024" - .0046" .0036" - .0064"

Cobalt Chrome > 40 90 - 180 .0007" - .0014" .0008" - .0017" .0010" - .0021" .0014" - .0028" .0016" - .0034" .0020" - .0042" .0028" - .0056"

eghe di nichel /

leaciones de níquel / A

/ N

lliage de nickel / L

ierungen / A

ickelleg

高镍基合金

NICKEL BASE ALLOYS / Nickellegierungen / Aleaciones de níquel / Alliage de nickel / Leghe di nichel / 高镍基合金

Inconel-625/718, Waspaloy, Invar, < 40 105 - 220 .0009" - .0016" .0010" - .0019" .0012" - .0023" .0018" - .0032" .0020" - .0038" .0024" - .0046" .0036" - .0064"

Rene, Hastelloy, Monel > 40 90 - 180 .0007" - .0014" .0008" - .0017" .0010" - .0021" .0014" - .0028" .0016" - .0034" .0020" - .0042" .0028" - .0056"

S IRON BASE ALLOYS / Eisenlegierungen / Aleaciones ferrosas / Alliages ferreux / Leghe ferrose / 铁基合金

eghe f

er

er

ierungen / A

ose /

leaciones f

r

eux / L

/ Eisenleg

r

lliages f

er

osas / A

r

铁基合金

A286, Discaloy, Haynes 556, < 40 105 - 220 .0009" - .0016" .0010" - .0019" .0012" - .0023" .0018" - .0032" .0020" - .0038" .0024" - .0046" .0036" - .0064"

Carpenter 22, Greek Ascolloy > 40 90 - 180 .0007" - .0014" .0008" - .0017" .0010" - .0021" .0014" - .0028" .0016" - .0034" .0020" - .0042" .0028" - .0056"

lliage de

T

itanio /

T

itane / L

eghe di

T

leaciones de

itanio / A

/

T

itanleg

ierungen / A

钛合金

TITANIUM ALLOYS / Titanlegierungen / Aleaciones de Titanio / Alliage de Titane / Leghe di Titanio / 钛合金

Commercially Pure, 6Al-4V,

Astm 1/2/3, 6Al-25N-4Zr-2Mo-Si 240 - 450 .0010" - .0018" .0011" - .0021" .0013" - .0025" .0020" - .0036" .0022" - .0042" .0026" - .0050" .0040" - .0072"

5553 / Beta Titanium 180 - 340 .0010" - .0016" .0011" - .0019" .0013" - .0023" .0020" - .0032" .0022" - .0038" .0026" - .0046" .0040" - .0064"

no

o I

ostfr

x /

cier I

ciaio I

xidable / A

no

/ R

c

y

c

tähle / A

x

er

no

eie S

dable / A

STAINLESS STEELS / Rostfreie Stähle / Acero Inoxidable / Acier Inoxydable / Acciaio Inox / 不锈钢合金

不锈钢合金

< 40 300 - 450 .0009" - .0016" .0010" - .0019" .0012" - .0023" .0018" - .0032" .0020" - .0038" .0024" - .0046" .0036" - .0064"

13/8, 15/5, 17-4, pH Types > 40 210 - 330 .0007" - .0014" .0008" - .0017" .0010" - .0021" .0014" - .0028" .0016" - .0034" .0020" - .0042" .0028" - .0056"

M 300 Series, 304L, Nitronic 50, < 40 300 - 480 .0009" - .0016" .0010" - .0019" .0012" - .0023" .0018" - .0032" .0020" - .0038" .0024" - .0046" .0036" - .0064"

Duplex, Super-Austenitic > 40 210 - 330 .0007" - .0014" .0008" - .0017" .0010" - .0021" .0014" - .0028" .0016" - .0034" .0020" - .0042" .0028" - .0056"

< 40 270 - 510 .0009" - .0017" .0010" - .0020" .0012" - .0024" .0018" - .0034" .0020" - .0040" .0024" - .0048" .0036" - .0068"

400 Series - 403, 405, 420, 455

> 40 210 - 390 .0007" - .0015" .0008" - .0018" .0010" - .0022" .0014" - .0030" .0016" - .0036" .0020" - .0044" .0028" - .0060"

c

er

ciaio da ut

os de alt

ta ac

r

amien

o dur

W

ésistanc

ciers à outils a haut

e

est

e / A

/ Hochf

er

eugstähle / Her

kz

e r

o /

ensili molt

eza / A

o dur

高强度工具钢

HIGH STRENGTH TOOL STEELS / Hochfeste Werkzeugstähle / Herramienta aceros de alto dureza / Aciers à outils a haute résistance / Acciaio da utensili molto duro / 高强度工具钢

A2, D2, P20, H13, S7, O1 < 40 270 - 480 .0009" - .0017" .0010" - .0020" .0012" - .0024" .0018" - .0034" .0020" - .0040" .0024" - .0048" .0036" - .0068"

180 - 390

> 40

.0007" - .0014" .0008" - .0017" .0010" - .0021" .0014" - .0028" .0016" - .0034" .0020" - .0042" .0028" - .0056"

ezza /

c

ensili di media

ciaio da ut

ta medios de la aleación / A

ciers à outils alliés / A

dur

eugstähle / A

el L

e

eg

/ M

er

itt

kz

W

c

os her

r

amien

ier

t

er

合金钢

中碳

P MEDIUM ALLOY TOOL STEELS / Mittel Legierte Werkzeugstähle / Aceros herramienta medios de la aleación / Aciers à outils alliés / Acciaio da utensili di media durezza / 中碳合金钢

.0009" - .0018" .0010" - .0021" .0012" - .0025" .0018" - .0036" .0020" - .0042" .0024" - .0050" .0036" - .0072"

420 - 600

< 40

4140, 4340, 52100, 6150, 8620 > 40 300 - 450 .0007" - .0015" .0008" - .0018" .0010" - .0022" .0014" - .0030" .0016" - .0036" .0020" - .0044" .0028" - .0060"

off

/ Kohlenst

c

er

stahl / A

o de car

bonio /

c

bón / A

cier du car

ciaio al car

bone / A

碳钢

CARBON STEELS / Kohlenstoffstahl / Acero de carbón / Acier du carbone / Acciaio al carbonio / 碳钢

1000’s - 1018, 1020, 12L14 < 40 450 - 720 .0011" - .0019" .0012" - .0022" .0014" - .0026" .0022" - .0038" .0024" - .0044" .0028" - .0052" .0044" - .0076"

t

a

er

er

t

a

/ G

iaux f

egossenes M

tidos / M

t

es / M

ial bastidor v

t

er

t

a

a

on

er

iale fuso /

er

ial / M

CAST MATERIAL / Gegossenes Material / Material bastidor vertidos / Materiaux fontes / Materiale fuso / 铸造件

铸造件

K Ductile Iron 420 - 630 .0011" - .0019" .0012" - .0022" .0014" - .0026" .0022" - .0038" .0024" - .0044" .0028" - .0052" .0044" - .0076"

Gray Iron 540 - 710 .0012" - .0021" .0013" - .0024" .0015" - .0028" .0024" - .0042" .0026" - .0048" .0030" - .0056" .0048" - .0084"

Profile/Trochoidal ap

Milling

Axial (ap) up to 2xD ae

Radial (ae) 5% - 15% of Dia.

NOTE - ABOVE ARE STARTING PARAMETERS ONLY. HIGHER RESULTS MAY BE ACHIEVED WITH OPTIMUM CONDITIONS.

300 www.garrtool.com ®