Page 335 - GARR_TOOL(CATALOG_INT)

P. 335

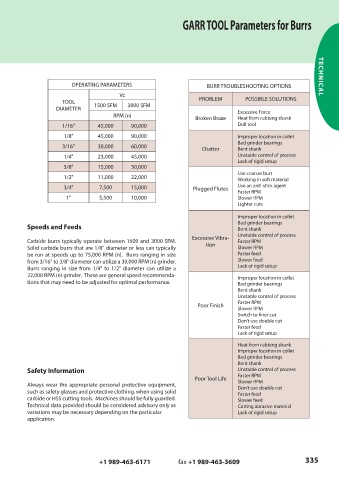

GARR TOOL Parameters for Burrs

OPERATING PARAMETERS BURR TROUBLESHOOTING OPTIONS TECHNICAL

Vc

TOOL PROBLEM POSSIBLE SOLUTIONS

DIAMETER 1500 SFM 3000 SFM Excessive Force

RPM (n) Broken Braze Heat from rubbing shank

1/16" 45,000 90,000 Dull tool

1/8" 45,000 90,000 Improper location in collet

Bad grinder bearings

3/16" 30,000 60,000 Chatter Bent shank

1/4" 23,000 45,000 Unstable control of process

Lack of rigid setup

3/8" 15,000 30,000

Use coarser burr

1/2" 11,000 22,000 Working in soft material

3/4" 7,500 15,000 Plugged Flutes Use an anti-stick agent

Faster RPM

1" 5,500 10,000 Slower RPM

Lighter cuts

Improper location in collet

Bad grinder bearings

Speeds and Feeds Bent shank

Excessive Vibra- Unstable control of process

Carbide burrs typically operate between 1500 and 3000 SFM. tion Faster RPM

Solid carbide burrs that are 1/8" diameter or less can typically Slower RPM

be run at speeds up to 75,000 RPM (n). Burrs ranging in size Faster feed

from 3/16" to 3/8" diameter can utilize a 30,000 RPM (n) grinder. Slower feed

Burrs ranging in size from 1/4" to 1/2" diameter can utilize a Lack of rigid setup

22,000 RPM (n) grinder. These are general speed recommenda- Improper location in collet

tions that may need to be adjusted for optimal performance. Bad grinder bearings

Bent shank

Unstable control of process

Poor Finish Faster RPM

Slower RPM

Switch to finer cut

Don’t use double cut

Faster feed

Lack of rigid setup

Heat from rubbing shank

Improper location in collet

Bad grinder bearings

Bent shank

Safety Information Unstable control of process

Poor Tool Life Faster RPM

Always wear the appropriate personal protective equipment, Slower RPM

Don’t use double cut

such as safety glasses and protective clothing, when using solid Faster feed

carbide or HSS cutting tools. Machines should be fully guarded. Slower feed

Technical data provided should be considered advisory only as Cutting abrasive material

variations may be necessary depending on the particular Lack of rigid setup

application.

+1 989-463-6171 fax +1 989-463-3609 335