Page 191 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 191

USER GUIDETION GUIDE

SELEC

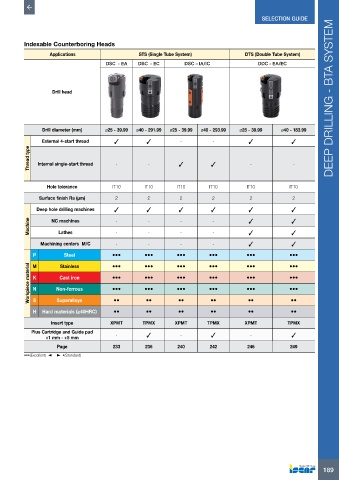

Indexable Counterboring Heads

Applications STS (Single Tube System) DTS (Double Tube System)

DSC - EA DSC - EC DSC – IA/IC DDC - EA/EC

Drill head DEEP DRILLING - BTA SYSTEM SOLID CARBIDE DRILLS

Drill diameter (mm) ø25 - 39.99 ø40 - 291.99 ø25 - 39.99 ø40 - 293.99 ø25 - 39.99 ø40 - 183.99

External 4-start thread 3 3 - - 3 3

Thread type Internal single-start thread - - 3 3 - -

Hole tolerance IT10 IT10 IT10 IT10 IT10 IT10

Surface finish Ra (μm) 2 2 2 2 2 2

Deep hole drilling machines 3 3 3 3 3 3

Machine NC machines - - - - - - - - 3 3

3

Lathes

3

Machining centers M/C - - - - 3 3

Steel

P Stainless ••• ••• ••• ••• ••• •••

•••

•••

•••

•••

•••

•••

Workpiece material K Non-ferrous ••• ••• ••• ••• ••• •••

M

Cast iron

•••

•••

•••

•••

N

•••

•••

S

Superalloys

••

••

••

••

••

••

H Hard materials (≥40HRC) •• •• •• •• •• ••

Insert type XPMT TPMX XPMT TPMX XPMT TPMX

Plus Cartridge and Guide pad - - -

+1 mm - +5 mm 3 3 3

Page 233 236 240 242 246 249

•••(Excellent) •(Standard)

189

189