Page 345 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 345

USER GUIDE

REAMERS

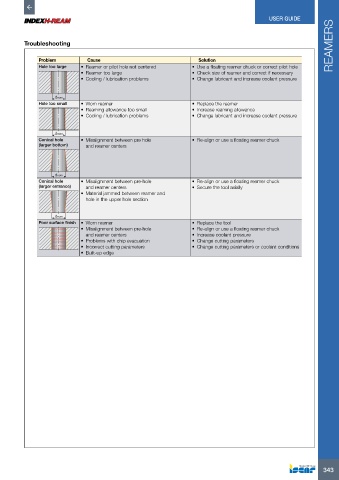

Troubleshooting

Problem Cause Solution

Hole too large • Reamer or pilot hole not centered • Use a floating reamer chuck or correct pilot hole

• Reamer too large • Check size of reamer and correct if necessary

• Cooling / lubrication problems • Change lubricant and increase coolant pressure

dnom

Hole too small • Worn reamer • Replace the reamer

• Reaming allowance too small • Increase reaming allowance

• Cooling / lubrication problems • Change lubricant and increase coolant pressure

dnom

Conical hole • Misalignment between pre hole • Re-align or use a floating reamer chuck

(larger bottom) and reamer centers

dnom

Conical hole • Misalignment between pre-hole • Re-align or use a floating reamer chuck

(larger entrance) and reamer centers • Secure the tool axially

• Material jammed between reamer and

hole in the upper hole section

dnom

Poor surface finish • Worn reamer • Replace the tool

• Misalignment between pre-hole • Re-align or use a floating reamer chuck

and reamer centers • Increase coolant pressure

• Problems with chip evacuation • Change cutting parameters

• Incorrect cutting parameters • Change cutting parameters or coolant conditions

• Built-up edge

343