Page 341 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 341

USER GUIDE

REAMERS

Concept

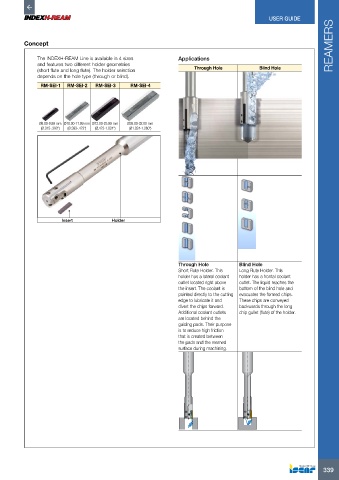

The INDEXH-REAM Line is available in 4 sizes Applications

and features two different holder geometries

(short flute and long flute). The holder selection Through Hole Blind Hole

depends on the hole type (through or blind).

RM-SEI-1 RM-SEI-2 RM-SEI-3 RM-SEI-4

Ø8.00-9.99 mm Ø10.00-11.99 mm Ø12.00-25.99 mm Ø26.00-32.00 mm

(Ø.315-.393") (Ø.393-.472") (Ø.472-1.024") (Ø1.024-1.260")

Insert Holder

Through Hole Blind Hole

Short Flute Holder. This Long Flute Holder. This

holder has a lateral coolant holder has a frontal coolant

outlet located right above outlet. The liquid reaches the

the insert. The coolant is bottom of the blind hole and

pointed directly to the cutting evacuates the formed chips.

edge to lubricate it and These chips are conveyed

divert the chips forward. backwards through the long

Additional coolant outlets chip gullet (flute) of the holder.

are located behind the

guiding pads. Their purpose

is to reduce high friction

that is created between

the pads and the reamed

surface during machining.

339