Page 354 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 354

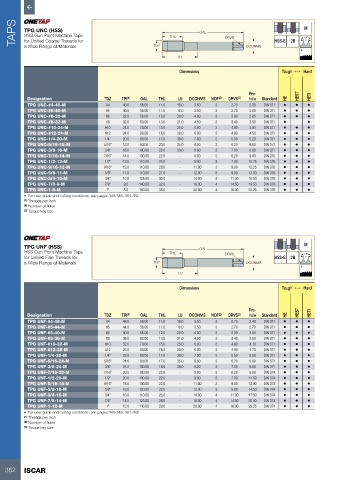

TAPS TPG UNC (HSS) THL OAL DRVS HSS-E 2B M P

HSS Gun Point Machine Taps

60˚

for Unified Coarse Threads for

a Wide Range of Materials

TDZ

DCONMS

B

LU

Dimensions Tough 1 Hard

Pre-

Designation TDZ TPI (1) OAL THL LU DCONMS NOF (2) DRVS (3) hole Standard HE HEST HETI

TPG UNC-#4-40-M #4 40.0 56.00 11.0 18.0 3.50 3 2.70 2.30 DIN 371 • • •

TPG UNC-#5-40-M #5 40.0 56.00 11.0 18.0 3.50 3 2.70 2.60 DIN 371 • • •

TPG UNC-#6-32-M #6 32.0 56.00 12.0 20.0 4.00 3 3.00 2.85 DIN 371 • • •

TPG UNC-#8-32-M #8 32.0 63.00 13.0 21.0 4.50 3 3.40 3.50 DIN 371 • •

TPG UNC-#10-24-M #10 24.0 70.00 15.0 25.0 6.00 3 4.90 3.90 DIN 371 • • •

TPG UNC-#12-24-M #12 24.0 80.00 16.0 30.0 6.00 3 4.90 4.50 DIN 371 • • •

TPG UNC-1/4-20-M 1/4" 20.0 80.00 17.0 30.0 7.00 3 5.50 5.20 DIN 371 • • •

TPG UNC-5/16-18-M 5/16" 18.0 90.00 20.0 35.0 8.00 3 6.20 6.60 DIN 371 • • •

TPG UNC-3/8-16-M 3/8" 16.0 100.00 22.0 39.0 9.00 3 7.00 8.00 DIN 371 • • •

TPG UNC-7/16-14-M 7/16" 14.0 100.00 22.0 - 8.00 3 6.20 9.40 DIN 376 • • •

TPG UNC-1/2-13-M 1/2" 13.0 110.00 25.0 - 9.00 3 7.00 10.75 DIN 376 • • •

TPG UNC-9/16-12-M 9/16" 12.0 110.00 26.0 - 11.00 3 9.00 12.25 DIN 376 • • •

TPG UNC-5/8-11-M 5/8" 11.0 110.00 27.0 - 12.00 3 9.00 13.50 DIN 376 • • •

TPG UNC-3/4-10-M 3/4" 10.0 125.00 30.0 - 14.00 4 11.00 16.50 DIN 376 • • •

TPG UNC-7/8-9-M 7/8" 9.0 140.00 32.0 - 18.00 4 14.50 19.50 DIN 376 • • •

TPG UNC-1-8-M 1" 8.0 160.00 36.0 - 20.00 4 16.00 22.25 DIN 376 • • •

• For user guide and cutting conditions, see pages 346-348, 361-382

(1) Threads per inch

(2) Number of flutes

(3) Torque key size

TPG UNF (HSS) OAL M

HSS Gun Point Machine Taps THL DRVS 60˚

for Unified Fine Threads for HSS-E 2B P

a Wide Range of Materials TDZ DCONMS

B

LU

Dimensions Tough 1 Hard

Pre-

Designation TDZ TPI (1) OAL THL LU DCONMS NOF (2) DRVS (3) hole Standard HE HEST HETI

TPG UNF-#4-48-M #4 48.0 56.00 11.0 18.0 3.50 3 2.70 2.40 DIN 371 • • •

TPG UNF-#5-44-M #5 44.0 56.00 11.0 18.0 3.50 3 2.70 2.70 DIN 371 • • •

TPG UNF-#6-40-M #6 40.0 56.00 12.0 20.0 4.00 3 3.00 3.00 DIN 371 • • •

TPG UNF-#8-36-M #8 36.0 63.00 13.0 21.0 4.50 3 3.40 3.50 DIN 371 • • •

TPG UNF-#10-32-M #10 32.0 70.00 15.0 25.0 6.00 3 4.90 4.10 DIN 371 • • •

TPG UNF-#12-28-M #12 28.0 80.00 16.0 30.0 6.00 3 4.90 4.70 DIN 371 • • •

TPG UNF-1/4-28-M 1/4" 28.0 80.00 17.0 30.0 7.00 3 5.50 5.50 DIN 371 • • •

TPG UNF-5/16-24-M 5/16" 24.0 90.00 17.0 35.0 8.00 3 6.20 6.90 DIN 371 • • •

TPG UNF-3/8-24-M 3/8" 24.0 100.00 18.0 39.0 9.00 3 7.00 8.50 DIN 371 • • •

TPG UNF-7/16-20-M 7/16" 20.0 100.00 22.0 - 8.00 3 6.20 9.90 DIN 374 • • •

TPG UNF-1/2-20-M 1/2" 20.0 100.00 22.0 - 9.00 3 7.00 11.50 DIN 374 • • •

TPG UNF-9/16-18-M 9/16" 18.0 100.00 22.0 - 11.00 3 9.00 12.90 DIN 374 • • •

TPG UNF-5/8-18-M 5/8" 18.0 100.00 22.0 - 12.00 3 9.00 14.50 DIN 374 • • •

TPG UNF-3/4-16-M 3/4" 16.0 110.00 25.0 - 14.00 4 11.00 17.50 DIN 374 • • •

TPG UNF-7/8-14-M 7/8" 14.0 125.00 26.0 - 18.00 4 14.50 20.50 DIN 374 • • •

TPG UNF-1-12-M 1" 12.0 140.00 28.0 - 20.00 4 16.00 23.25 DIN 374 • • •

• For user guide and cutting conditions, see pages 346-348, 361-382

(1) Threads per inch

(2) Number of flutes

(3) Torque key size

352 ISCAR