Page 400 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 400

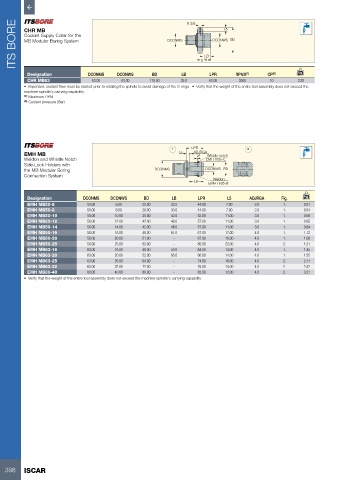

ITS BORE CHR MB DCONMS R 3/8 LPR DCONWS BD

15

Coolant Supply Collar for the

MB Modular Boring System

LB

Designation DCONMS DCONWS BD LB LPR RPMX (1) CP (2) kg

CHR MB63 63.00 63.00 115.00 35.0 63.00 3500 10 3.30

• Important: coolant flow must be started prior to rotating the spindle to avoid damage of the O-rings • Verify that the weight of the entire tool assembly does not exceed the

machine spindle's carrying capability.

(1) Maximum RPM

(2) Coolant pressure (Bar)

1 LPR 2

EMH MB L5 ADJRGA Whistle notch

2º

Weldon and Whistle Notch EMH 1835-E

Side-Lock Holders with

the MB Modular Boring DCONMS DCONWS BD

Connection System

Weldon

LB EMH 1835-B

Designation DCONMS DCONWS BD LB LPR L5 ADJRGA Fig. kg

EMH MB50-6 50.00 6.00 25.00 32.5 44.00 7.00 2.0 1. 0.51

EMH MB50-8 50.00 8.00 28.00 33.0 44.00 7.00 2.0 1. 0.54

EMH MB50-10 50.00 10.00 35.00 42.0 52.00 11.00 3.0 1. 0.68

EMH MB50-12 50.00 12.00 42.00 48.0 57.00 11.00 3.0 1. 0.85

EMH MB50-14 50.00 14.00 42.00 48.0 57.00 11.00 3.0 1. 0.84

EMH MB50-16 50.00 16.00 48.00 61.0 67.00 17.00 4.0 1. 1.12

EMH MB50-20 50.00 20.00 51.00 - 67.00 16.00 4.0 1. 1.08

EMH MB50-25 50.00 25.00 63.00 - 80.00 22.00 4.0 2. 1.21

EMH MB63-16 63.00 16.00 48.00 53.0 64.00 14.00 4.0 1. 1.45

EMH MB63-20 63.00 20.00 52.00 56.0 66.00 14.00 4.0 1. 1.55

EMH MB63-25 63.00 25.00 64.00 - 74.00 16.00 4.0 2. 2.11

EMH MB63-32 63.00 32.00 72.00 - 76.00 14.00 4.0 2. 2.42

EMH MB80-40 80.00 40.00 80.00 - 83.00 12.00 4.0 2. 3.21

• Verify that the weight of the entire tool assembly does not exceed the machine spindle's carrying capability.

398 ISCAR