Page 408 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 408

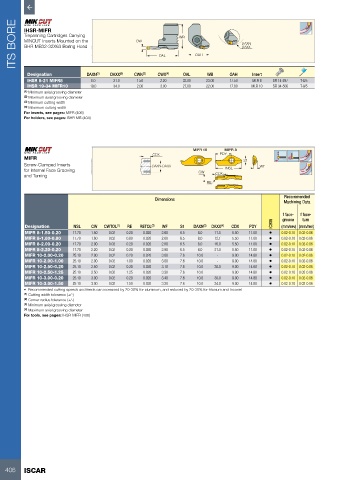

ITS BORE IHSR-MIFR CW OAL WB OAH DAXN

Trepanning Cartridges Carrying

MINCUT Inserts Mounted on the

BHR MB32-32X63 Boring Head

DAXX

Designation DAXN (1) DAXX (2) CWN (3) CWX (4) OAL WB OAH Insert

IHSR 8-21 MIFR8 8.0 21.0 1.50 2.20 32.00 23.00 17.50 MI.R 8 SR 14-297 T-8/5

IHSR 19-34 MIFR10 19.0 34.0 2.00 3.00 27.00 22.00 17.80 MI.R 10 SR 34-506 T-9/5

(1) Minimum axial grooving diameter

(2) Maximum axial grooving diameter

(3) Minimum cutting width

(4) Maximum cutting width

For inserts, see pages: MIFR (406)

For holders, see pages: BHR MB (404)

MIFR 10 MIFR 8

MIFR CDX PDY S1

Screw-Clamped Inserts DAXN-DAXX WF

for Internal Face Grooving CW INSL

and Turning CDX

RE

Dimensions Recommended

Machining Data

f face- f face-

IC908 groove turn

Designation INSL CW CWTOL (1) RE RETOL (2) WF S1 DAXN (3) DAXX (4) CDX PDY (mm/rev) (mm/rev)

MIFR 8-1.50-0.20 17.70 1.50 0.02 0.20 0.020 2.60 6.5 8.0 11.5 5.50 11.00 • 0.02-0.10 0.02-0.06

MIFR 8-1.60-0.80 17.70 1.60 0.02 0.80 0.020 2.60 6.5 8.0 12.1 5.50 11.00 • 0.02-0.10 0.02-0.06

MIFR 8-2.00-0.20 17.70 2.00 0.02 0.20 0.020 2.80 6.5 8.0 16.0 5.50 11.00 • 0.02-0.10 0.02-0.06

MIFR 8-2.20-0.20 17.70 2.20 0.02 0.20 0.020 2.90 6.5 8.0 21.0 5.50 11.00 • 0.02-0.10 0.02-0.06

MIFR 10-2.00-0.20 25.10 2.00 0.02 0.20 0.020 3.00 7.6 10.0 - 9.00 14.80 • 0.02-0.10 0.02-0.06

MIFR 10-2.00-1.00 25.10 2.00 0.02 1.00 0.020 3.00 7.6 10.0 - 9.00 14.80 • 0.02-0.10 0.02-0.06

MIFR 10-2.50-0.20 25.10 2.50 0.02 0.20 0.020 3.10 7.6 10.0 30.0 9.00 14.80 • 0.02-0.10 0.02-0.06

MIFR 10-2.50-1.25 25.10 2.50 0.02 1.25 0.020 3.30 7.6 10.0 - 9.00 14.80 • 0.02-0.10 0.02-0.06

MIFR 10-3.00-0.20 25.10 3.00 0.02 0.20 0.020 3.40 7.6 10.0 30.0 9.00 14.80 • 0.02-0.10 0.02-0.06

MIFR 10-3.00-1.50 25.10 3.00 0.02 1.50 0.020 3.30 7.6 10.0 34.0 9.00 14.80 • 0.02-0.10 0.02-0.06

• Recommended cutting speeds and feeds can increased by 20-30% for aluminum, and reduced by 20-30% for titanium and Inconel

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

(3) Minimum axial grooving diameter

(4) Maximum axial grooving diameter

For tools, see pages: IHSR-MIFR (406)

406 ISCAR