Page 558 - ISCAR(MILLINGCATALOG 38_2021)

P. 558

INTRODUCTION

TOOLING SYSTEMS

INTRODUCTION

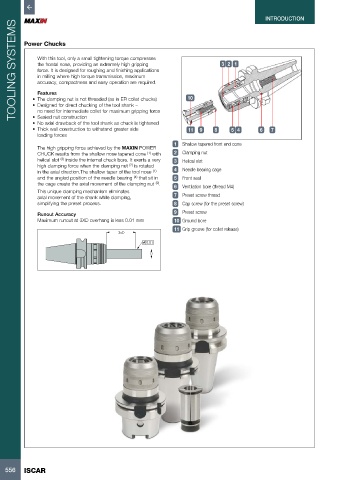

Power Chucks

With this tool, only a small tightening torque compresses

the frontal nose, providing an extremely high gripping 3 2 1

force. It is designed for roughing and finishing applications

in milling where high torque transmission, maximum

accuracy, compactness and easy operation are required.

Features

• The clamping nut is not threaded (as in ER collet chucks) 10

• Designed for direct chucking of the tool shank –

no need for intermediate collet for maximum gripping force

• Sealed nut construction

• No axial drawback of the tool shank as chuck is tightened

• Thick wall construction to withstand greater side 11 9 8 5 4 6 7

loading forces

1 Shallow tapered front end cone

The high gripping force achieved by the MAXIN POWER

(1)

CHUCK results from the shallow nose tapered cone with 2 Clamping nut

(3)

helical slot inside the internal chuck bore. It exerts a very 3 Helical slot

(2)

high clamping force when the clamping nut is rotated

(1)

in the axial direction.The shallow taper of the tool nose 4 Needle bearing cage

(4)

and the angled position of the needle bearing that sit in 5 Front seal

the cage create the axial movement of the clamping nut . 6 Ventilation bore (thread M4)

(2)

This unique clamping mechanism eliminates

axial movement of the shank while clamping, 7 Preset screw thread

simplifying the preset process. 8 Cap screw (for the preset screw)

Runout Accuracy 9 Preset screw

Maximum runout at 3XD overhang is less 0.01 mm 10 Ground bore

11 Grip groove (for collet release)

3xD

0.01

D

556 ISCAR