Page 681 - ISCAR(MILLINGCATALOG 38_2021)

P. 681

58-60 HRc

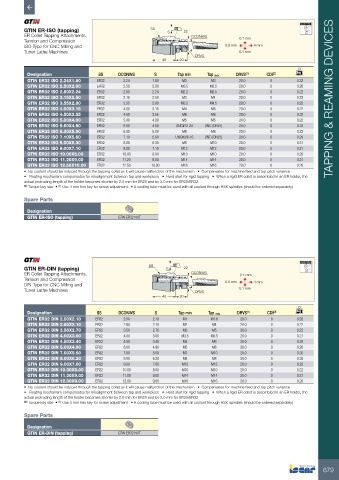

GTIN ER-ISO (tapping) SS S 22

ER Collet Tapping Attachments, DCONWS

Tension and Compression 0.1 mm

ISO Type for CNC Milling and 0.8 mm 4 mm

Turret Lathe Machines 0.1 mm

DRVS

40 20

Designation SS DCONWS S Tap min Tap max DRVS (1) CDI (2) kg

GTIN ER32 ISO 2.24X1.80 ER32 2.24 1.80 M3 M3 20.0 0 0.22

GTIN ER32 ISO 2.50X2.00 ER32 2.50 2.00 M3.5 M3.5 20.0 0 0.26

GTIN ER32 ISO 2.80X2.24 ER32 2.80 2.24 M2.2 M2.5 20.0 0 0.22

GTIN ER32 ISO 3.15X2.50 ER32 3.15 2.50 M3 M4 20.0 0 0.23 TAPPING & REAMING DEVICES

GTIN ER32 ISO 3.55X2.80 ER32 3.55 2.80 M3.5 M4.5 20.0 0 0.22

GTIN ER32 ISO 4.00X3.15 ER32 4.00 3.15 M4 M5 20.0 0 0.22

GTIN ER32 ISO 4.50X3.55 ER32 4.50 3.55 M6 M6 20.0 0 0.22

GTIN ER32 ISO 5.00X4.00 ER32 5.00 4.00 M5 M5 20.0 0 0.22

GTIN ER32 ISO 5.60X4.50 ER32 5.60 4.50 UNC#12-24 UNC (ONLY) 20.0 0 0.23

GTIN ER32 ISO 6.30X5.00 ER32 6.30 5.00 M6 M8 20.0 0 0.22

GTIN ER32 ISO 7.10X5.60 ER32 7.10 5.60 UNC#3/8-16 UNC (ONLY) 20.0 0 0.20

GTIN ER32 ISO 8.00X6.30 ER32 8.00 6.30 M8 M10 20.0 0 0.21

GTIN ER32 ISO 9.00X7.10 ER32 9.00 7.10 M12 M12 20.0 0 0.21

GTIN ER32 ISO 10.00X8.00 ER32 10.00 8.00 M10 M10 20.0 0 0.20

GTIN ER32 ISO 11.20X9.00 ER32 11.20 9.00 M14 M14 20.0 0 0.21

GTIN ER32 ISO 12.50X10.00 ER32 12.50 10.00 M16 M16 20.0 0 0.20

• No coolant should be induced through the tapping collet as it will cause malfunction of the mechanism • Compensates for machine feed and tap pitch variance

• Floating mechanism compensates for misalignment between tap and workpiece • Hard start for rigid tapping • When a rigid ER collet is assembled in an ER holder, the

actual protruding length of the holder becomes shorter by 2.0 mm for ER20 and by 3.0 mm for ER25/ER32

(1) Torque key size • (1) Use 4 mm hex key for screw adjustment. • A cooling tube must be used with all coolant through HSK spindles (should be ordered separately)

Spare Parts

Designation

GTIN ER-ISO (tapping) GTIN ER32 NUT

58-60 HRc

GTIN ER-DIN (tapping) SS S 22

ER Collet Tapping Attachments, DCONWS 0.1 mm

Tension and Compression 0.8 mm

DIN Type for CNC Milling and 4 mm

Turret Lathe Machines DRVS 0.1 mm

40 20

Designation SS DCONWS S Tap min Tap max DRVS (1) CDI (2) kg

GTIN ER32 DIN 2.50X2.10 ER32 2.50 2.10 M1 M1.8 20.0 0 0.20

GTIN ER32 DIN 2.80X2.10 ER32 2.80 2.10 M2 M4 20.0 0 0.22

GTIN ER32 DIN 3.50X2.70 ER32 3.50 2.70 M3 M5 20.0 0 0.22

GTIN ER32 DIN 4.00X3.00 ER32 4.00 3.00 M3.5 M3.5 20.0 0 0.21

GTIN ER32 DIN 4.50X3.40 ER32 4.50 3.40 M4 M6 20.0 0 0.20

GTIN ER32 DIN 6.00X4.90 ER32 6.00 4.90 M5 M8 20.0 0 0.20

GTIN ER32 DIN 7.00X5.50 ER32 7.00 5.50 M7 M10 20.0 0 0.20

GTIN ER32 DIN 8.00X6.20 ER32 8.00 6.20 M8 M8 20.0 0 0.20

GTIN ER32 DIN 9.00X7.00 ER32 9.00 7.00 M12 M12 20.0 0 0.22

GTIN ER32 DIN 10.00X8.00 ER32 10.00 8.00 M10 M10 20.0 0 0.22

GTIN ER32 DIN 11.00X9.00 ER32 11.00 9.00 M14 M14 20.0 0 0.21

GTIN ER32 DIN 12.00X9.00 ER32 12.00 9.00 M16 M16 20.0 0 0.20

• No coolant should be induced through the tapping collet as it will cause malfunction of the mechanism • Compensates for machine feed and tap pitch variance

• Floating mechanism compensates for misalignment between tap and workpiece • Hard start for rigid tapping • When a rigid ER collet is assembled in an ER holder, the

actual protruding length of the holder becomes shorter by 2.0 mm for ER20 and by 3.0 mm for ER25/ER32

(1) Torque key size • (1) Use 4 mm hex key for screw adjustment. • A cooling tube must be used with all coolant through HSK spindles (should be ordered separately)

Spare Parts

Designation

GTIN ER-DIN (tapping) GTIN ER32 NUT

679