Page 676 - ISCAR(MILLINGCATALOG 38_2021)

P. 676

USER GUIDE

CENTER ALIGNMENT DEVICES

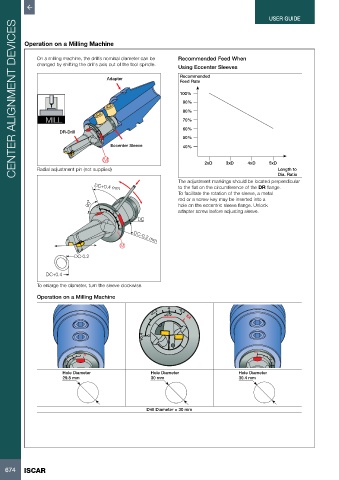

Operation on a Milling Machine

On a milling machine, the drill’s nominal diameter can be Recommended Feed When

changed by shifting the drill’s axis out of the tool spindle.

Using Eccenter Sleeves

Recommended

Adapter

Feed Rate

100%

90%

80%

MILL 70%

+0.4

0 60%

DR-Drill +0.2

50%

0

+0.2

-0.2

L

Eccenter Sleeve 40%

M

2xD 3xD 4xD 5xD

Radial adjustment pin (not supplied) Length to

Dia. Ratio

The adjustment markings should be located perpendicular

DC+0.4 mm to the flat on the circumference of the DR flange.

To facilitate the rotation of the sleeve, a metal

rod or a screw key may be inserted into a

90 +0.4 hole on the eccentric sleeve flange. Unlock

0 +0.2 adapter screw before adjusting sleeve.

DC

0

+0.2

-0.2 L

M DC-0.2 mm

DC-0.2

DC+0.4

To enlarge the diameter, turn the sleeve clockwise.

Operation on a Milling Machine

0

+0.2 +0.2 -0.2

L M

+0.4 0

+0.4

-0.2 M

0 L 0 +0.2

+0.2 +0.2 +0.2 0

Hole Diameter Hole Diameter Hole Diameter L -0.2 M

+0.4

29.8 mm 30 mm 30.4 mm

Drill Diameter = 30 mm

674 ISCAR