Page 727 - ISCAR(MILLINGCATALOG 38_2021)

P. 727

USER GUIDE

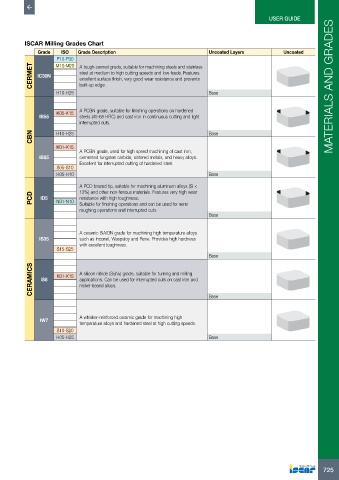

ISCAR Milling Grades Chart

Grade ISO Grade Description Uncoated Layers Uncoated

P10-P30 A tough cermet grade, suitable for machining steels and stainless

M10-M20

CERMET IC30N steel at medium to high cutting speeds and low feeds. Features

excellent surface finish, very good wear resistance and prevents

built-up edge.

H10-H25 Base MATERIALS AND GRADES

K05-K15 A PCBN grade, suitable for finishing operations on hardened

IB55 steels (45-65 HRC) and cast iron in continuous cutting and light

interrupted cuts.

CBN H10-H25 Base

K01-K15

A PCBN grade, used for high speed machining of cast iron,

IB85 cemented tungsten carbide, sintered metals, and heavy alloys.

Excellent for interrupted cutting of hardened steel.

S05-S10

H05-H10 Base

A PCD brazed tip, suitable for machining aluminum alloys (Si <

12%) and other non-ferrous materials. Features very high wear

PCD ID5 N01-N10 resistance with high toughness.

Suitable for finishing operations and can be used for semi

roughing operations and interrupted cuts.

Base

A ceramic SiAlON grade for machining high temperature alloys

IS35 such as Inconel, Waspaloy and Rene. Provides high hardness

with excellent toughness.

S15-S25

Base

CERAMICS IS8 K01-K15 A silicon nitride (Si3N4) grade, suitable for turning and milling Base

applications. Can be used for interrupted cuts on cast iron and

nickel-based alloys.

A whisker-reinforced ceramic grade for machining high

IW7

temperature alloys and hardened steel at high cutting speeds.

S10-S20

H05-H25 Base

725