Page 726 - ISCAR(MILLINGCATALOG 38_2021)

P. 726

USER GUIDE

MATERIALS AND GRADES

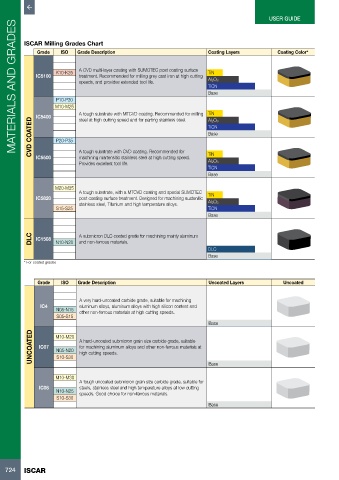

ISCAR Milling Grades Chart

Grade ISO Grade Description Coating Layers Coating Color*

A CVD multi-layer coating with SUMOTEC post coating surface

K10-K25 TiN

IC5100 treatment. Recommended for milling grey cast iron at high cutting

speeds, and provides extended tool life. Al2O3

TiCN

Base

P10-P20

M10-M25

A tough substrate with MTCVD coating. Recommended for milling TiN

IC5400 steel at high cutting speed and for parting stainless steel. Al2O3

CVD COATED P20-P35 Base

TiCN

A tough substrate with CVD coating. Recommended for

IC5500

machining martensitic stainless steel at high cutting speed.

Al2O3

Provides excellent tool life. TiN

TiCN

Base

M20-M35

A tough substrate, with a MTCVD coating and special SUMOTEC TiN

IC5820 post coating surface treatment. Designed for machining austenitic

stainless steel, Titanium and high temperature alloys. Al2O3

S15-S25 TiCN

Base

DLC IC1508 N10-N20 A submicron DLC coated grade for machining mainly aluminum

and non-ferrous materials.

DLC

Base

* For coated grades

Grade ISO Grade Description Uncoated Layers Uncoated

A very hard-uncoated carbide grade, suitable for machining

IC4 aluminum alloys, aluminum alloys with high silicon content and

N05-N15 other non-ferrous materials at high cutting speeds.

S05-S15

Base

UNCOATED IC07 M10-M20 A hard-uncoated submicron grain size carbide grade, suitable

for machining aluminum alloys and other non-ferrous materials at

N05-N20

high cutting speeds.

S10-S30

M10-M30 Base

A tough uncoated submicron grain size carbide grade, suitable for

IC08 steels, stainless steel and high temperature alloys at low cutting

N10-N25 speeds. Good choice for non-ferrous materials.

S10-S30

Base

724 ISCAR