Page 131 - ISCAR(TURNING-CATALOG-42-2022)

P. 131

USER GUIDE

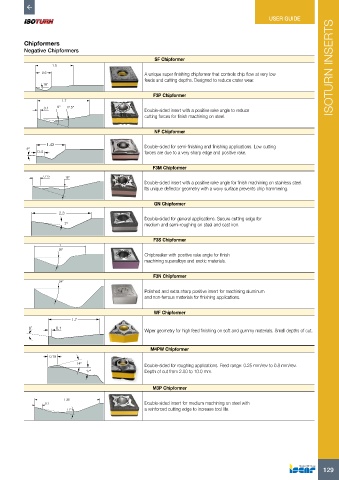

Chipformers

Negative Chipformers

SF Chipformer

1.5 ISOTURN INSERTS

0.6 A unique super finishing chipformer that controls chip flow at very low

feeds and cutting depths. Designed to reduce crater wear.

18˚

F3P Chipformer

1.7

0.1 6° 12.5° Double-sided insert with a positive rake angle to reduce

cutting forces for finish machining on steel.

NF Chipformer

1.42 Double-sided for semi-finishing and finishing applications. Low cutting

4º

0.4 forces are due to a very sharp edge and positive rake.

F3M Chipformer

0.15 15°

Double-sided insert with a positive rake angle for finish machining on stainless steel.

Its unique deflector geometry with a wavy surface prevents chip hammering.

GN Chipformer

Double-sided for general applications. Secure cutting edge for

medium and semi-roughing on steel and cast iron.

F3S Chipformer

1

20°

Chipbreaker with positive rake angle for finish

machining superalloys and exotic materials.

F3N Chipformer

24°

Polished and extra sharp positive insert for machining aluminum

and non-ferrous materials for finishing applications.

WF Chipformer

1.7

8˚ 0.1

Wiper geometry for high feed finishing on soft and gummy materials. Small depths of cut.

M4PW Chipformer

0.19

14º

Double-sided for roughing applications. Feed range: 0.25 mm/rev to 0.8 mm/rev.

17º Depth of cut from 2.00 to 10.0 mm.

M3P Chipformer

1.35

0.1 Double-sided insert for medium machining on steel with

11° a reinforced cutting edge to increase tool life.

129