Page 132 - ISCAR(TURNING-CATALOG-42-2022)

P. 132

USER GUIDE

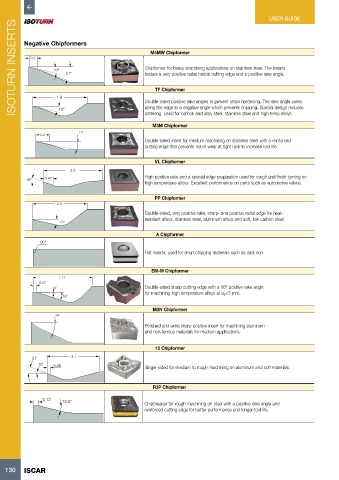

ISOTURN INSERTS Negative Chipformers Chipformer for heavy machining applications on stainless steel. The inserts

M4MW Chipformer

0.3

13º

21º

feature a very positive radial helical cutting edge and a positive rake angle.

TF Chipformer

Double-sided positive rake angles to prevent strain hardening. The rake angle varies

along the edge to a negative angle which prevents chipping. Special design reduces

cratering. Used for carbon and alloy steel, stainless steel and high-temp alloys.

M3M Chipformer

11°

0.2

Double-sided insert for medium machining on stainless steel with a reinforced

cutting edge that prevents notch wear at tight radii to increase tool life.

VL Chipformer

3.3

16° 0.47 High positive rake and a special edge preparation used for rough and finish turning on

high temperature alloys. Excellent performance on parts such as automotive valves.

PP Chipformer

Double-sided, very positive rake, sharp- and positive radial edge for heat-

resistant alloys, stainless steel, aluminum alloys and soft, low carbon steel.

A Chipformer

90°

Flat inserts, used for short chipping materials such as cast iron.

EM-M Chipformer

1.11

0.07

5˚ Double-sided sharp cutting edge with a 16º positive rake angle

for machining high temperature alloys at ap<3 mm.

16˚

M3N Chipformer

24°

Polished and extra sharp positive insert for machining aluminum

and non-ferrous materials for medium applications.

12 Chipformer

21˚ 2.7

10˚ 0.08 Single-sided for medium to rough machining on aluminum and soft materials.

R3P Chipformer

0.12

13.5° Chipbreaker for rough machining on steel with a positive rake angle and

reinforced cutting edge for better performance and longer tool life.

130 ISCAR