Page 243 - ISCAR(TURNING-CATALOG-42-2022)

P. 243

USER GUIDE

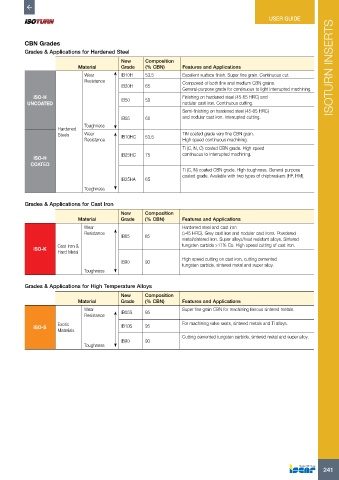

CBN Grades

Grades & Applications for Hardened Steel

New Composition

Material Grade (% CBN) Features and Applications ISOTURN INSERTS

Wear IB10H 53.5 Excellent surface finish. Super fine grain. Continuous cut.

Resistance Composed of both fine and medium CBN grains.

IB20H 65

General-purpose grade for continuous to light interrupted machining.

ISO-H IB50 50 Finishing on hardened steel (45-65 HRC) and

UNCOATED nodular cast iron. Continuous cutting.

Semi-finishing on hardened steel (45-65 HRC)

IB55 60 and nodular cast iron. Interrupted cutting.

Toughness

Hardened

Steels Wear IB10HC 53.5 TiN coated grade very fine CBN grain.

Resistance High speed continuous machining.

Ti (C, N, O) coated CBN grade. High speed

ISO-H IB25HC 75 continuous to interrupted machining.

COATED

Ti (C, N) coated CBN grade. High toughness. General purpose

coated grade. Available with two types of chipbreakers (HF, HM).

IB25HA 65

Toughness

Grades & Applications for Cast Iron

New Composition

Material Grade (% CBN) Features and Applications

Wear Hardened steel and cast iron

Resistance (>45 HRC). Grey cast iron and nodular cast irons. Powdered

IB85 85

metal/sintered iron. Super alloys/heat resistant alloys. Sintered

Cast Iron & tungsten carbide >17% Co. High speed cutting of cast iron.

ISO-K

Hard Metal

High speed cutting on cast iron, cutting cemented

IB90 90

tungsten carbide, sintered metal and super alloy.

Toughness

Grades & Applications for High Temperature Alloys

New Composition

Material Grade (% CBN) Features and Applications

Wear IB05S 95 Super fine grain CBN for machining ferrous sintered metals.

Resistance

Exotic For machining valve seats, sintered metals and Ti alloys.

ISO-S IB10S 95

Materials

Cutting cemented tungsten carbide, sintered metal and super alloy.

IB90 90

Toughness

241