Page 355 - ISCAR(TURNING-CATALOG-42-2022)

P. 355

UR UL

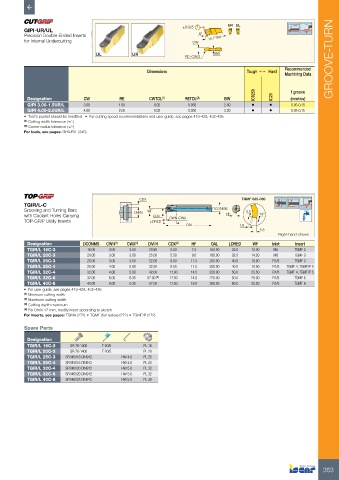

GIPI-UR/UL ±0.025

Precision Double-Ended Inserts 8° 15.7 Ref.

for Internal Undercutting CW

BW

RE=CW/2 GROOVE-TURN

Dimensions Tough 1 Hard Recommended

Machining Data

IC8250 f groove

Designation CW RE CWTOL (1) RETOL (2) BW IC20 (mm/rev)

GIPI 3.00-1.5UR/L 3.00 1.50 0.02 0.050 2.40 • • 0.05-0.15

GIPI 4.00-2.0UR/L 4.00 2.00 0.02 0.050 3.20 • • 0.05-0.15

• Tool's pocket should be modified • For cutting speed recommendations and user guide, see pages 419-428, 432-436

(1) Cutting width tolerance (+/-)

(2) Corner radius tolerance (+/-)

For tools, see pages: GHIUR/L (345)

CDX TGMF 635-080

TGIR/L-C

Grooving and Turning Bars DMIN WF DCONMS 0.5

with Coolant Holes Carrying CDX CWN-CWX HF 19°

TOP-GRIP Utility Inserts LDRED

OAL 1.6

5.5

Right-hand shown

Designation DCONMS CWN (1) CWX (2) DMIN CDX (3) HF OAL LDRED WF Inlet Insert

TGIR/L 16C-3 16.00 3.00 3.00 20.50 5.50 7.5 150.00 25.0 12.00 M6 TGMF 3

TGIR/L 20C-3 20.00 3.00 3.00 25.00 5.50 9.0 180.00 32.0 14.20 M6 TGMF 3

TGIR/L 25C-3 25.00 3.00 3.00 32.00 8.00 11.5 200.00 40.0 18.80 R1/8 TGMF 3

TGIR/L 25C-4 25.00 4.00 5.00 32.50 8.50 11.5 200.00 40.0 19.50 R1/8 TGMF 4, TGMF/P 5

TGIR/L 32C-4 32.00 4.00 5.00 42.00 11.00 14.5 220.00 50.0 25.50 R1/8 TGMF 4, TGMF/P 5

TGIR/L 32C-6 32.00 6.00 6.35 57.00 (4) 17.50 14.5 220.00 50.0 29.00 R1/8 TGMF 6

TGIR/L 40C-6 40.00 6.00 6.35 57.00 17.50 18.0 300.00 60.0 35.20 R1/8 TGMF 6

• For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Cutting depth maximum

(4) For Dmin 47 mm, modify insert according to sketch

For inserts, see pages: TGMA (272) • TGMF (full radius) (272) • TGMF/P (272)

Spare Parts

Designation

TGIR/L 16C-3 SR 76-1400 T-20/5 PL 16

TGIR/L 20C-3 SR 76-1400 T-20/5 PL 20

TGIR/L 25C-3 SR M5X16 DIN912 HW 4.0 PL 25

TGIR/L 25C-4 SR M5X16 DIN912 HW 4.0 PL 25

TGIR/L 32C-4 SR M6X20 DIN912 HW 5.0 PL 32

TGIR/L 32C-6 SR M6X20 DIN912 HW 5.0 PL 32

TGIR/L 40C-6 SR M6X25 DIN912 HW 5.0 PL 40

353