Page 358 - ISCAR(TURNING-CATALOG-42-2022)

P. 358

GROOVE-TURN GHIC-85 32.0 DCONMS DCONMS HF 18.0 H SR M6X16 DIN912 HW 5.0

Boring Bars for Internal

Grooving and Turning

Blades, DMIN=85 mm

OAL

OAL

H

Designation

HF

GHIC 40-85

260.00

40.00

GHIC 50-85

For tools, see pages: CGHN 32-DGM (358) • CGHN 32-M (357)

• For both right and left hand applications 32.0 50.00 300.00 23.0 SR M6X16 DIN912 HW 5.0

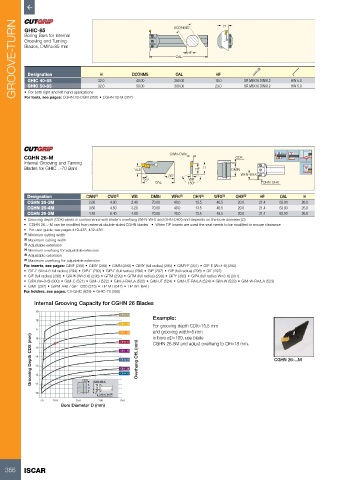

CGHN 26-M CWN-CWX CDX

Internal Grooving and Turning

Blades for GHIC...-70 Bars 14.5 HF H DMIN

35° WFN-WFX

25° WB

OAL 150° OHN-OHX

Designation CWN (1) CWX (2) WB DMIN WFN (3) OHN (4) WFX (5) OHX (6) HF OAL H

CGHN 26-3M 2.80 4.00 2.40 70.00 40.0 13.5 46.5 20.0 21.4 63.00 26.0

CGHN 26-4M 3.60 4.50 3.20 70.00 40.0 13.5 46.5 20.0 21.4 63.00 26.0

CGHN 26-5M 4.40 6.40 4.00 70.00 40.0 13.5 46.5 20.0 21.4 63.00 26.0

• Grooving depth (CDX) varies in conformance with blade's overhang (WFN-WFX and OHN-OHX) and depends on the bore diameter (D)

• CGHN 26...-M can be modified from external double-sided CGHN blades • When TIP inserts are used the seat needs to be modified to ensure clearance

• For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Adjustable extension

(4) Minimum overhang for adjustable extension

(5) Adjustable extension

(6) Maximum overhang for adjustable extension

For inserts, see pages: GIMF (288) • GIMY (288) • GIMN (289) • GIMY (full radius) (290) • GIMY-F (291) • GIF-E (W=4-6) (292)

• GIF-E (W=4-6 full radius) (294) • GIP-E (293) • GIP-E (full radius) (294) • GIP (297) • GIP (full radius) (296) • GIF (297)

• GIF (full radius) (298) • GIA-K (W=3-6) (298) • GITM (299) • GITM (full radius) (299) • GIPY (300) • GIPA (full radius W=3-6) (301)

• GIPA (W=3-6) (300) • GIM-C (521) • GIM-J (522) • GIM-J-RA/LA (522) • GIM-UT (524) • GIM-UT-RA/LA (524) • GIM-W (523) • GIM-W-RA/LA (523)

• GIMT (287) • GIPM-A46 / GIP-1250 (375) • TIP-MT (647) • TIP-WT (641)

For holders, see pages: C#-GHIC (629) • GHIC-70 (355)

Internal Grooving Capacity for CGHN 26 Blades

19

OH=20

Example:

18

OH=19 For grooving depth CDX=15.5 mm

17

OH=18 and grooving width=5 mm

Grooving Depth CDX (mm) 15 OH=16 Overhang OH, (mm) CGHN 26-...M

in bore øD=100, use blade

16

OH=17

CGHN 26-5M and adjust overhang to OH=18 mm.

14

OH=15

13

OH=14

OH=13

12

CDX

11

D WFN-WFX

10

OHN-OHX (1)

70 100 150 200 250

Bore Diameter D (mm)

356 ISCAR