Page 292 - GARR_TOOL(CATALOG_INT)

P. 292

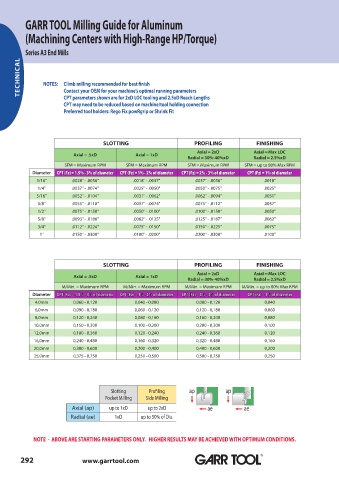

GARR TOOL Milling Guide for Aluminum

(Machining Centers with High-Range HP/Torque)

Series A3 End Mills

TECHNICAL NOTES: Climb milling recommended for best finish

Contact your OEM for your machine’s optimal running parameters

CPT may need to be reduced based on machine/tool holding connection

CPT parameters shown are for 2xD LOC tooling and 2.5xD Reach Lengths

Preferred tool holders: Rego Fix powRgrip or Shrink Fit

SLOTTING PROFILING FINISHING

Axial = 2xD Axial = Max LOC

=

=

Axial = .5xD Axial = 1xD

Radial = 30%-40%xD Radial = 2.5%xD

=

=

SFM = Maximum RPM SFM = Maximum RPM SFM = Maximum RPM SFM = up to 80% Max RPM

er

CPT (Fz) = 1.5% - 3% of diameter

CPT (Fz) = 2% - 3% of diameter

CPT (Fz) = 1% - 2% of diamet

CPT (Fz) = 1% of diameter

Diameter CPT (Fz) = 1.5% - 3% of diamet er CPT (Fz) = 1% - 2% of diameter CPT (Fz) = 2% - 3% of diamet er CPT (Fz) = 1% of diamet er

3/16" .0028" - .0056" .0018" - .0037" .0037" - .0056" .0018"

1/4" .0037" - .0074" .0025" - .0050" .0050" - .0075" .0025"

5/16" .0052" - .0104" .0031" - .0062" .0062" - .0094" .0031"

3/8" .0055" - .0110" .0037" - .0074" .0075" - .0112" .0037"

1/2" .0075" - .0150" .0050" - .0100" .0100" - .0150" .0050"

5/8" .0093" - .0186" .0062" - .0125" .0125" - .0187" .0062"

3/4" .0112" - .0224" .0075" - .0150" .0150" - .0225" .0075"

1" .0150" - .0300" .0100" - .0200" .0200" - .0300" .0100"

SLOTTING PROFILING FINISHING

=

=

Axial = 2xD Axial = Max LOC

Axial = .5xD Axial = 1xD

Radial = 30%-40%xD Radial = 2.5%xD

=

=

M/Min. = Maximum RPM M/Min. = Maximum RPM M/Min. = Maximum RPM M/Min. = up to 80% Max RPM

er

er

CPT (Fz) = 2% - 3% of diamet

CPT (Fz) = 1% of diamet

er

CPT (Fz) = 1.5% - 3% of diameter

CPT (Fz) = 1% - 2% of diamet

Diameter CPT (Fz) = 1.5% - 3% of diamet er CPT (Fz) = 1% - 2% of diameter CPT (Fz) = 2% - 3% of diameter CPT (Fz) = 1% of diameter

4,0mm 0,060 - 0,120 0,040 - 0,080 0,080 - 0,120 0,040

6,0mm 0,090 - 0,180 0,060 - 0,120 0,120 - 0,180 0,060

8,0mm 0,120 - 0,240 0,080 - 0,160 0,160 - 0,240 0,080

10,0mm 0,150 - 0,300 0,100 - 0,200 0,200 - 0,300 0,100

12,0mm 0,180 - 0,360 0,120 - 0,240 0,240 - 0,360 0,120

16,0mm 0,240 - 0,480 0,160 - 0,320 0,320 - 0,480 0,160

20,0mm 0,300 - 0,600 0,200 - 0,400 0,400 - 0,600 0,200

25,0mm 0,375 - 0,750 0,250 - 0,500 0,500 - 0,750 0,250

Slotting Profiling ap ap

Pocket Milling Side Milling

Axial (ap) up to 1xD up to 2xD ae ae

Radial (ae) 1xD up to 50% of Dia.

NOTE - ABOVE ARE STARTING PARAMETERS ONLY. HIGHER RESULTS MAY BE ACHIEVED WITH OPTIMUM CONDITIONS.

292 www.garrtool.com ®