Page 150 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 150

USER GUIDE

MULTIFUNCTION TOOLS

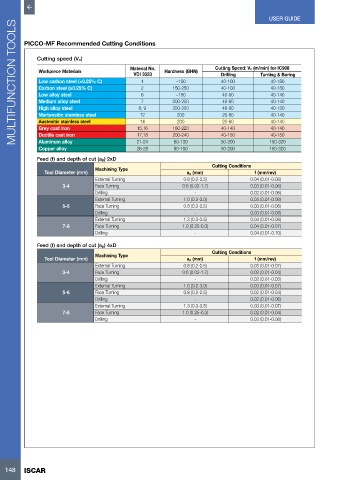

PICCO-MF Recommended Cutting Conditions

Cutting speed (Vc)

Material No. Cutting Speed: Vc (m/min) for IC908

Workpiece Materials Hardness (BHN)

VDI 3323 Drilling Turning & Boring

Low carbon steel (<0.25% C) 1 ~150 40-100 40-180

Carbon steel (≥0.25% C) 2 150-250 40-100 40-180

Low alloy steel 6 ~180 40-80 40-140

Medium alloy steel 7 200-250 40-80 40-140

High alloy steel 8, 9 250-350 40-60 40-120

Martensitic stainless steel 12 200 20-60 40-140

Austenitic stainless steel 14 200 20-60 40-140

Grey cast iron 15,16 180-220 40-140 40-140

Ductile cast iron 17,18 200-240 40-150 40-150

Aluminum alloy 21-24 60-130 50-200 150-320

Copper alloy 26-28 90-100 50-200 150-320

Feed (f) and depth of cut (ap) 2xD

Cutting Conditions

Machining Type

Tool Diameter (mm) ap (mm) f (mm/rev)

External Turning 0.8 (0.2-2.5) 0.04 (0.01-0.08)

3-4 Face Turning 0.6 (0.02-1.7) 0.03 (0.01-0.06)

Drilling - 0.02 (0.01-0.06)

External Turning 1.0 (0.2-3.0) 0.04 (0.01-0.08)

5-6 Face Turning 0.8 (0.2-2.5) 0.03 (0.01-0.06)

Drilling - 0.03 (0.01-0.08)

External Turning 1.3 (0.3-3.5) 0.04 (0.01-0.08)

7-8 Face Turning 1.0 (0.25-0.3) 0.04 (0.01-0.07)

Drilling - 0.04 (0.01-0.10)

Feed (f) and depth of cut (ap) 4xD

Cutting Conditions

Machining Type

Tool Diameter (mm) ap (mm) f (mm/rev)

External Turning 0.8 (0.2-2.5) 0.03 (0.01-0.07)

3-4 Face Turning 0.6 (0.02-1.7) 0.02 (0.01-0.04)

Drilling - 0.02 (0.01-0.05)

External Turning 1.0 (0.2-3.0) 0.03 (0.01-0.07)

5-6 Face Turning 0.8 (0.2-2.5) 0.02 (0.01-0.04)

Drilling - 0.02 (0.01-0.06)

External Turning 1.3 (0.3-3.5) 0.03 (0.01-0.07)

7-8 Face Turning 1.0 (0.25-0.3) 0.02 (0.01-0.04)

Drilling - 0.03 (0.01-0.08)

148 ISCAR