Page 146 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 146

USER GUIDE

MULTIFUNCTION TOOLS

User guide for DRG-MF User Guide for Turn-Mill Machines

Coolant Pressure Insert Positioning

• Apply above 6 Bar in 2.25xD tools (optimal pressure For drilling, cutting edge should be positioned in the center

is above 10 Bar). of tool body.

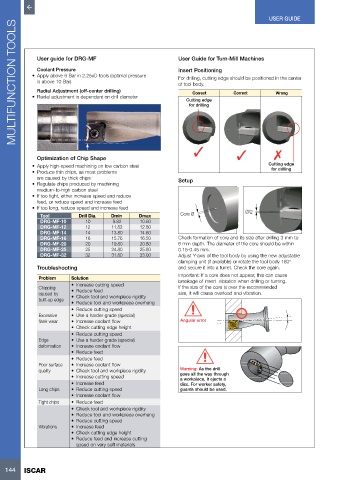

Radial Adjustment (off-center drilling) Correct Correct Wrong

• Radial adjustment is dependent on drill diameter

Cutting edge

for drilling

Optimization of Chip Shape

• Apply high-speed machining on low carbon steel Cutting edge

• Produce thin chips, as most problems for drilling

are caused by thick chips Setup

• Regulate chips produced by machining

medium-to-high carbon steel

• If too tight, either increase speed and reduce

feed, or reduce speed and increase feed

• If too long, reduce speed and increase feed Ø/2

Tool Drill Dia. Dmin Dmax Core Ø

DRG-MF-10 10 9.82 10.60

DRG-MF-12 12 11.82 12.60

DRG-MF-14 14 13.80 14.60

DRG-MF-16 16 15.76 16.50 Check formation of core and its size after drilling 3 mm to

DRG-MF-20 20 19.80 20.60 6 mm depth. The diameter of the core should be within

DRG-MF-25 25 24.80 25.80 0.15-0.45 mm.

DRG-MF-32 32 31.80 33.00 Adjust Y-axis of the tool body by using the new adjustable

clamping unit (if available) or rotate the tool body 180°

Troubleshooting and secure it into a turret. Check the core again.

Important: If a core does not appear, this can cause

Problem Solution breakage of insert vibration when drilling or turning.

• Increase cutting speed

Chipping • Reduce feed If the size of the core is over the recommended

caused by • Check tool and workpiece rigidity size, it will cause overload and vibration.

built-up edge

• Reduce tool and workpiece overhang

• Reduce cutting speed

Excessive • Use a harder grade (special)

flank wear • Increase coolant flow Angular error

• Check cutting edge height

• Reduce cutting speed

Edge • Use a harder grade (special)

deformation • Increase coolant flow

• Reduce feed

• Reduce feed

Poor surface • Increase coolant flow

quality • Check tool and workpiece rigidity Warning: As the drill

• Increase cutting speed goes all the way through

a workpiece, it ejects a

• Increase feed disc. For worker safety,

Long chips • Reduce cutting speed guards should be used.

• Increase coolant flow

Tight chips • Reduce feed

• Check tool and workpiece rigidity

• Reduce tool and workpiece overhang

• Reduce cutting speed

Vibrations • Increase feed

• Check cutting edge height

• Reduce feed and increase cutting

speed on very soft materials

144 ISCAR