Page 183 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 183

USER GUIDE

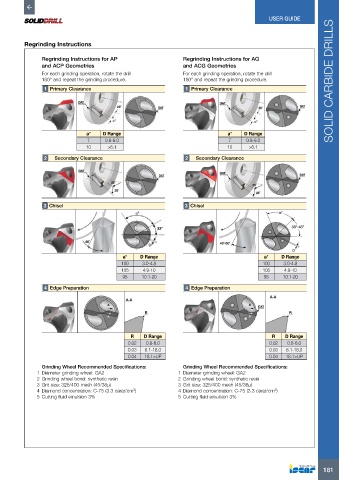

Regrinding Instructions

Regrinding Instructions for AP Regrinding Instructions for AG

and ACP Geometries and ACG Geometries

For each grinding operation, rotate the drill For each grinding operation, rotate the drill

180° and repeat the grinding procedure. 180° and repeat the grinding procedure. SOLID CARBIDE DRILLS

1 Primary Clearance 1 Primary Clearance

a° D Range a° D Range

7 0.8-6.0 7 0.8-6.0

10 >6.1 10 >6.1

2 Secondary Clearance 2 Secondary Clearance

3 Chisel 3 Chisel

a° D Range a° D Range

100 3.0-4.8 100 3.0-4.8

105 4.9-10 105 4.9-10

95 10.1-20 95 10.1-20

4 Edge Preparation 4 Edge Preparation

R D Range R D Range

0.02 0.8-6.0 0.02 0.8-6.0

0.03 6.1-18.0 0.03 6.1-18.0

0.04 18.1>UP 0.04 18.1>UP

Grinding Wheel Recommended Specifications: Grinding Wheel Recommended Specifications:

1 Diameter grinding wheel: GA2 1 Diameter grinding wheel: GA2

2 Grinding wheel bond: synthetic resin 2 Grinding wheel bond: synthetic resin

3 Grit size: 325/400 mesh (45/38µ) 3 Grit size: 325/400 mesh (45/38µ)

3

3

4 Diamond concentration: C-75 (3.3 carat/cm ) 4 Diamond concentration: C-75 (3.3 carat/cm )

5 Cutting fluid emulsion 3% 5 Cutting fluid emulsion 3%

181