Page 185 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 185

USER GUIDE

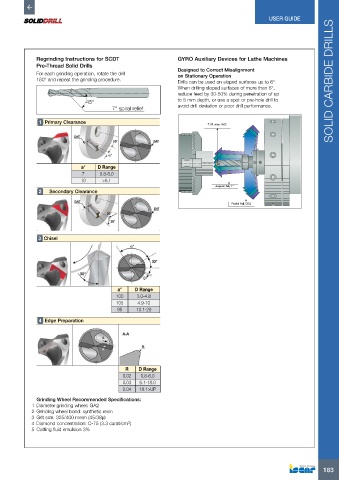

Regrinding Instructions for SCDT GYRO Auxiliary Devices for Lathe Machines

Pre-Thread Solid Drills Designed to Correct Misalignment

For each grinding operation, rotate the drill on Stationary Operation

180° and repeat the grinding procedure.

Drills can be used on sloped surfaces up to 6°. SOLID CARBIDE DRILLS

When drilling sloped surfaces of more than 6°,

reduce feed by 30-50% during penetration of up

45° to 5 mm depth, or use a spot or pre-hole drill to

7° spiral relief avoid drill deviation or poor drill performance.

1 Primary Clearance

T.I.R. max. 0.02

a° D Range

7 0.8-6.0

10 >6.1

Angular Adj. 1°

2 Secondary Clearance

Radial Adj. D2.0

3 Chisel

a° D Range

100 3.0-4.8

105 4.9-10

95 10.1-20

4 Edge Preparation

R D Range

0.02 0.8-6.0

0.03 6.1-18.0

0.04 18.1>UP

Grinding Wheel Recommended Specifications:

1 Diameter grinding wheel: GA2

2 Grinding wheel bond: synthetic resin

3 Grit size: 325/400 mesh (45/38µ)

3

4 Diamond concentration: C-75 (3.3 carat/cm )

5 Cutting fluid emulsion 3%

183