Page 184 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 184

USER GUIDE

SOLID CARBIDE DRILLS

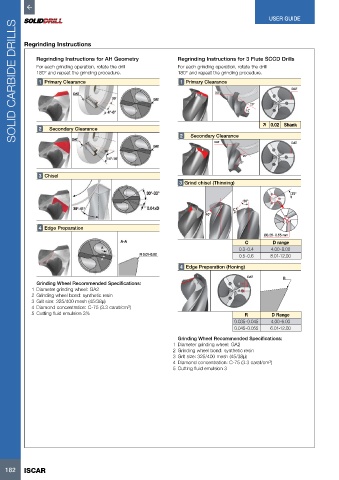

Regrinding Instructions

Regrinding Instructions for AH Geometry Regrinding Instructions for 3 Flute SCCD Drills

For each grinding operation, rotate the drill For each grinding operation, rotate the drill

180° and repeat the grinding procedure. 180° and repeat the grinding procedure.

1 Primary Clearance 1 Primary Clearance

DAT

D

DAT

AT

20°

10˚

0.02 Shank

2 Secondary Clearance

2 Secondary Clearance

DAT DAT

20°

20°

25°

25°

3 Chisel

3 Grind chisel (Thinning)

35°

30°

C

40°

4 Edge Preparation

Ø0.25- 0.55 mm

C D range

0.3-0.4 4.00-8.00

0.5-0.6 8.01-12.00

4 Edge Preparation (Honing)

DAT R

Grinding Wheel Recommended Specifications: A

1 Diameter grinding wheel: GA2 A

2 Grinding wheel bond: synthetic resin

3 Grit size: 325/400 mesh (45/38µ)

3

4 Diamond concentration: C-75 (3.3 carat/cm )

5 Cutting fluid emulsion 3% R D Range

0.035-0.045 4.00-6.00

0.045-0.055 6.01-12.00

Grinding Wheel Recommended Specifications:

1 Diameter grinding wheel: GA2

2 Grinding wheel bond: synthetic resin

3 Grit size: 325/400 mesh (45/38µ)

3

4 Diamond concentration: C-75 (3.3 carat/cm )

5 Cutting fluid emulsion 3

182 ISCAR