Page 312 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 312

USER GUIDE

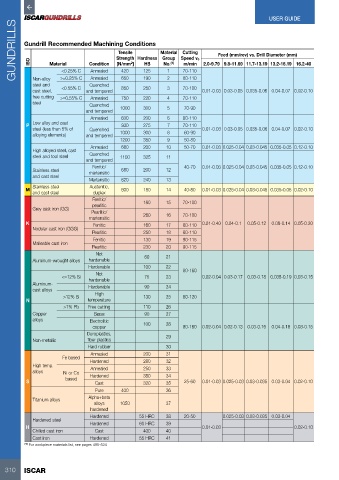

GUNDRILLS Gundrill Recommended Machining Conditions Material Cutting 2.0-9.79 9.8-11.69 11.7-13.19 13.2-16.19 16.2-40

Tensile

Feed (mm/rev) vs. Drill Diameter (mm)

Strength Hardness Group Speed vc

ISO

No.

Condition

HB

Material

[N/mm ]

2

(1)

m/min

Annealed

<0.25% C

Annealed

650

80-110

190

Non-alloy

steel and >=0.25% C Quenched 420 125 1 2 70-110

cast steel, <0.55% C and tempered 850 250 3 70-100 0.01-0.03 0.03-0.05 0.035-0.06 0.04-0.07 0.02-0.10

free cutting >=0.55% C Annealed 750 220 4 70-110

steel Quenched

and tempered 1000 300 5 70-90

Annealed 600 200 6 80-110

P Low alloy and cast 930 275 7 70-110

steel (less than 5% of Quenched 0.01-0.03 0.03-0.05 0.035-0.06 0.04-0.07 0.02-0.10

alloying elements) and tempered 1000 300 8 60-90

1200 350 9 50-80

Annealed 680 200 10 50-70 0.01-0.03 0.025-0.04 0.03-0.045 0.035-0.05 0.12-0.10

High alloyed steel, cast

steel and tool steel Quenched 1100 325 11

and tempered

Ferritic/ 40-70 0.01-0.03 0.025-0.04 0.03-0.045 0.035-0.05 0.12-0.10

Stainless steel martensitic 680 200 12

and cast steel

Martensitic 820 240 13

Stainless steel Austenitic,

M 600 180 14 40-80 0.01-0.03 0.025-0.04 0.03-0.045 0.035-0.05 0.02-0.10

and cast steel duplex

Ferritic/

pearlitic 180 15 70-100

Grey cast iron (GG)

Pearlitic/

martensitic 260 16 70-100

K Ferritic 160 17 80-110 0.01-0.40 0.04-0.1 0.05-0.12 0.06-0.14 0.05-0.20

Nodular cast iron (GGG)

Pearlitic 250 18 80-110

Ferritic 130 19 90-115

Malleable cast iron

Pearlitic 230 20 90-115

Not 60 21

Aluminum-wrought alloys hardenable

Hardenable 100 22 80-160

Not

<=12% Si hardenable 75 23 0.02-0.04 0.03-0.17 0.03-0.18 0.035-0.19 0.03-0.15

Aluminum-

cast alloys Hardenable 90 24

>12% Si High 130 25 80-120

N temperature

>1% Pb Free cutting 110 26

Copper Brass 90 27

alloys Electrolitic

copper 100 28 80-180 0.02-0.04 0.02-0.13 0.03-0.16 0.04-0.18 0.03-0.15

Duroplastics, 29

Non-metallic fiber plastics

Hard rubber 30

Annealed 200 31

Fe based

Hardened 280 32

High temp. Annealed 250 33

alloys Ni or Co Hardened 350 34

S based Cast 320 35 25-60 0.01-0.03 0.025-0.03 0.03-0.035 0.03-0.04 0.02-0.10

Pure 400 36

Titanium alloys Alpha+beta

alloys 1050 37

hardened

Hardened 55 HRC 38 20-50 0.025-0.03 0.03-0.035 0.03-0.04

Hardened steel

H Hardened 60 HRC 39 0.01-0.03 0.02-0.10

Chilled cast iron Cast 400 40

Cast iron Hardened 55 HRC 41

(1) For workpiece materials list, see pages 495-524

310 ISCAR