Page 320 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 320

USER GUIDE

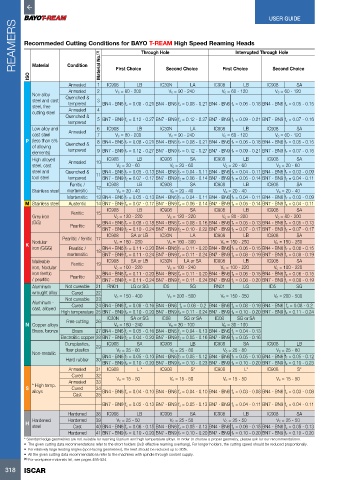

REAMERS Recommeded Cutting Conditions for BAYO T-REAM High Speed Reaming Heads

Through Hole

Interrupted Through Hole

ISO Material Condition Material No. (1) First Choice Second Choice First Choice Second Choice

Annealed 1 IC908 LB IC30N LA IC908 LB IC908 SA

Annealed 2 Vc = 80 - 200 Vc = 90 - 240 Vc = 60 - 120 Vc = 60 - 120

Non-alloy Quenched &

steel and cast tempered 3

steel, free Annealed 4 BN4 - BN6 fz = 0.08 - 0.21 BN4 - BN6 fz = 0.08 - 0.21 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.05 - 0.15

cutting steel

Quenched & 5 BN7 - BN9 fz = 0.12 - 0.27 BN7 - BN9 fz = 0.12 - 0.27 BN7 - BN9 fz = 0.09 - 0.21 BN7 - BN9 fz = 0.07 - 0.16

tempered

Low alloy and 6 IC908 LB IC30N LA IC908 LB IC908 SA

cast steel Annealed 7 Vc = 80 - 200 Vc = 90 - 240 Vc = 60 - 120 Vc = 60 - 120

P (less than 5% 8 BN4 - BN6 fz = 0.08 - 0.21 BN4 - BN6 fz = 0.08 - 0.21 BN4 - BN6 fz = 0.06 - 0.18 BN4 - BN6 fz = 0.05 - 0.15

of alloying Quenched &

elements) tempered 9 BN7 - BN9 fz = 0.12 - 0.27 BN7 - BN9 fz = 0.12 - 0.27 BN7 - BN9 fz = 0.09 - 0.21 BN7 - BN9 fz = 0.07 - 0.16

High alloyed Annealed 10 IC908 LB IC908 SA IC908 LB IC908 SA

steel, cast Vc = 20 - 60 Vc = 20 - 60 Vc = 20 - 60 Vc = 20 - 60

steel and Quenched & BN4 - BN6 fz = 0.05 - 0.13 BN4 - BN6 fz = 0.04 - 0.11 BN4 - BN6 fz = 0.04 - 0.11 BN4 - BN6 fz = 0.03 - 0.09

tool steel tempered 11 BN7 - BN9 fz = 0.07 - 0.17 BN7 - BN9 fz = 0.06 - 0.14 BN7 - BN9 fz = 0.05 - 0.14 BN7 - BN9 fz = 0.04 - 0.11

Ferritic / IC908 LB IC908 SA IC908 LB IC908 SA

Stainless steel martensitic 12 Vc = 20 - 40 Vc = 20 - 40 Vc = 20 - 40 Vc = 20 - 40

Martensitic 13 BN4 - BN6 fz = 0.05 - 0.13 BN4 - BN6 fz = 0.04 - 0.11 BN4 - BN6 fz = 0.04 - 0.11 BN4 - BN6 fz = 0.03 - 0.09

M Stainless steel Austentic 14 BN7 - BN9 fz = 0.07 - 0.17 BN7 - BN9 fz = 0.06 - 0.14 BN7 - BN9 fz = 0.05 - 0.14 BN7 - BN9 fz = 0.04 - 0.11

IC908 LB IC908 SA IC908 LB IC908 SA

Ferritic 15

Grey iron Vc = 120 - 220 Vc = 120 - 220 Vc = 80 - 200 Vc = 80 - 200

(GG) BN4 - BN6 fz = 0.08 - 0.18 BN4 - BN6 fz = 0.08 - 0.16 BN4 - BN6 fz = 0.05 - 0.13 BN4 - BN6 fz = 0.05 - 0.13

Pearlitic 16

BN7 - BN9 fz = 0.10 - 0.24 BN7 - BN9 fz = 0.10 - 0.22 BN7 - BN9 fz = 0.07 - 0.17 BN7 - BN9 fz = 0.07 - 0.17

IC908 SA or LB IC30N LA IC908 LB IC908 SA

Pearlitic / ferritic 17

Nodular Vc = 160 - 280 Vc = 160 - 300 Vc = 150 - 250 Vc = 150 - 250

K

iron (GGG) Pearlitic / 18 BN4 - BN6 fz = 0.11 - 0.20 BN4 - BN6 fz = 0.11 - 0.20 BN4 - BN6 fz = 0.06 - 0.15 BN4 - BN6 fz = 0.06 - 0.15

martensitic BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.08 - 0.19 BN7 - BN9 fz = 0.08 - 0.19

Malleable Ferritic 19 IC908 SA or LB IC30N LA or SA IC908 LB IC908 SA

iron, Nodular Vc = 100 - 220 Vc = 100 - 240 Vc = 100 - 220 Vc = 100 - 220

iron ferritic BN4 - BN6 fz = 0.11 - 0.20 BN4 - BN6 fz = 0.11 - 0.20 BN4 - BN6 fz = 0.06 - 0.15 BN4 - BN6 fz = 0.06 - 0.15

/ pearlitic Pearlitic 20 BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.08 - 0.20 BN7 - BN9 fz = 0.08 - 0.19

Aluminum Not cureable 21 RN01 LG or SG ID5 SG RN01 LG ID5 SG

wrought alloy Cured 22

Not cureable 23 Vc = 150 - 400 Vc = 200 - 500 Vc = 150 - 350 Vc = 200 - 500

Aluminum - Cured 24 BN4 - BN6 fz = 0.08 - 0.16 BN4 - BN6 fz = 0.08 - 0.2 BN4 - BN6 fz = 0.08 - 0.16 BN4 - BN6 fz = 0.08 - 0.2

cast, alloyed

High temperature 25 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.11 - 0.24 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.11 - 0.24

IC30N SA or SG IC08 SG or SA IC08 SG or SA

Free cutting 26

N Copper alloys Vc = 180 - 240 Vc = 30 - 100 Vc = 30 - 100

Brass, bronze Brass 27 BN4 - BN6 fz = 0.05 - 0.16 BN4 - BN6 fz = 0.04 - 0.13 BN4 - BN6 fz = 0.04 - 0.13

Electrolitic copper 28 BN7 - BN9 fz = 0.04 - 0.20 BN7 - BN9 fz = 0.05 - 0.16 BN7 - BN9 fz = 0.05 - 0.16

Duroplastics, 29 IC908 SA IC908 LB IC908 SA IC908 LB

fiber plastics Vc = 25 - 80 Vc = 25 - 80 Vc = 25 - 80 Vc = 25 - 80

Non-metallic

Hard rubber 30 BN4 - BN6 fz = 0.05 - 0.10 BN4 - BN6 fz = 0.05 - 0.12 BN4 - BN6 fz = 0.05 - 0.10 BN4 - BN6 fz = 0.05 - 0.12

BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.23 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.23

Annealed 31 IC908 L * IC908 S* IC908 L* IC908 S*

Cured 32

Annealed 33 Vc = 15 - 50 Vc = 15 - 50 Vc = 15 - 50 Vc = 15 - 50

* High temp.

S Cured 34

alloys BN4 - BN6 fz = 0.04 - 0.10 BN4 - BN6 fz = 0.04 - 0.10 BN4 - BN6 fz = 0.03 - 0.08 BN4 - BN6 fz = 0.03 - 0.08

Cast 35

BN7 - BN9 fz = 0.05 - 0.13 BN7 - BN9 fz = 0.05 - 0.13 BN7 - BN9 fz = 0.04 - 0.11 BN7 - BN9 fz = 0.04 - 0.11

Hardened 38 IC908 LB IC908 SA IC908 LB IC908 SA

Hardened Hardened 39 Vc = 25 - 50 Vc = 25 - 50 Vc = 25 - 50 Vc = 25 - 50

H

steel Cast 40 BN4 - BN6 fz = 0.06 - 0.15 BN4 - BN6 fz = 0.05 - 0.13 BN4 - BN6 fz = 0.06 - 0.15 BN4 - BN6 fz = 0.05 - 0.13

Hardened 41 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.20 BN7 - BN9 fz = 0.10 - 0.20

* Standard edge geometries are not suitable for reaming titanium and high temperature alloys. In order to choose a proper geometry, please ask for our recommendations.

• The given cutting data recommendations refer to the short holders (3xD effective reaming overhang). For longer holders, the cutting speed should be reduced proportionally.

• For relatively large leading angles (spot-facing geometries), the feed should be reduced up to 30%.

• All the given cutting data recommendations refer to the machines with spindle through coolant supply.

(1) For workpiece materials list, see pages 495-524

318 ISCAR