Page 322 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 322

USER GUIDE

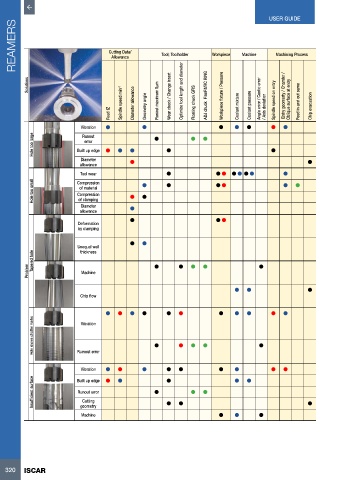

REAMERS Cutting Data/ Tool; Toolholder Workpiece Machine Machining Process

Allowance

Solutions Wear check / Change insert Optimize tool length and diameter ADJ chuck FineFit/RC RING Workpiece fixture / Pressure Angle error / Centic error Entry geomerty / Chamfer / Oblique surface at entry

Feed fZ Spindle speed min -1 Diameter allowance Geometry angle Runout maximum 5µm Floating chuck GFIS Coolant mixture Coolant pressure / Axis deviation Spindle speed on entry Feed in and out same Chip evacuation

• • • • • • •

Vibration

Hole too large Built up edge • • • • • • • •

Runout

error

Diameter • •

allowance

• •• •••• •

Tool wear

•

Hole too small Compression • • • •• • •

of material

Compression

of clamping

Diameter •

allowance

• ••

Deformation

by clamping

• •

Unequal wall

thickness

Tapered hole • • • • •

Problem Machine

• • •

Chip flow

• • • • • • • • • • •

Hole shows chatter marks Rumout error • • • • •

Vibration

• • • • • • • • •

Vibration • • • • •

Insufficient surface Built up edge • • • • • •

Runout error

Cutting

geometry

Machine • • •

320 ISCAR