Page 92 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 92

USER GUIDE

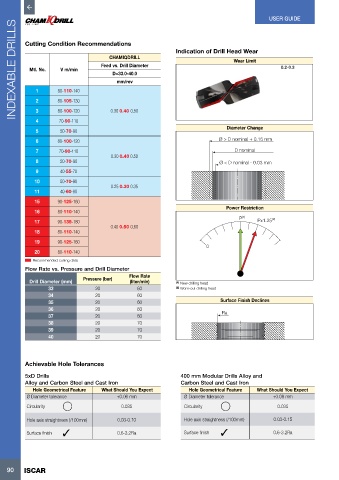

INDEXABLE DRILLS Mtl. No. 80-110-140 Feed vs. Drill Diameter Indication of Drill Head Wear 0.2-0.3

Cutting Condition Recommendations

CHAMIQDRILL

Wear Limit

V m/min

D=33.0-40.0

mm/rev

1

2

3

80-100-120

4 80-105-130 0.30 0.40 0.50

70-90-110

Diameter Change

5 50-70-90

6 80-100-120 Ø > D nominal + 0.15 mm

7 70-90-110 D nominal

0.30 0.40 0.50

8 50-70-90 Ø < D nominal - 0.03 mm

9 40-55-70

10 50-70-90

0.25 0.30 0.35

11 40-60-80

15 90-125-160

Power Restriction

16 80-110-140

P (1) (2)

17 90-135-180 Px1.25

0.40 0.50 0.60

18 80-110-140

19 90-125-160

0

20 80-110-140

Recommended cutiing data

Flow Rate vs. Pressure and Drill Diameter

Flow Rate

Drill Diameter (mm) Pressure (bar) (liter/min) (1) New drilling head

33 20 60 (2) Worn-out drilling head

34 20 60

35 20 60 Surface Finish Declines

36 20 60

37 20 60 Ra

38 20 70

39 20 70

40 20 70

Achievable Hole Tolerances

5xD Drills 400 mm Modular Drills Alloy and

Alloy and Carbon Steel and Cast Iron Carbon Steel and Cast Iron

Hole Geometrical Feature What Should You Expect Hole Geometrical Feature What Should You Expect

Ø Diameter tolerance +0.06 mm Ø Diameter tolerance +0.06 mm

Circularity 0.035 Circularity 0.035

Hole axis straightness (/100mm) 0.03-0.10 Hole axis straightness (/100mm) 0.03-0.15

Surface finish 0.6-3.2Ra Surface finish 0.6-3.2Ra

90 ISCAR