Page 87 - ISCAR(HOLE_MAKING_CATALOG_65)

P. 87

USER GUIDE

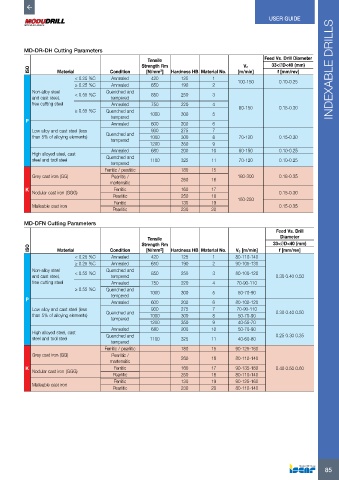

MD-DR-DH Cutting Parameters

Tensile Feed Vs. Drill Diameter

ISO Material Condition Strength Rm Hardness HB Material No. [m/min] 33<ØD<40 (mm) INDEXABLE DRILLS

Vc

[N/mm ]

f [mm/rev]

2

< 0.25 %C Annealed 420 125 1 100-150 0.10-0.25

≥ 0.25 %C Annealed 650 190 2

Non-alloy steel < 0.55 %C Quenched and 850 250 3

and cast steel, tempered

free cutting steel Annealed 750 220 4

≥ 0.55 %C Quenched and 80-150 0.15-0.30

tempered 1000 300 5

P

Annealed 600 200 6

Low alloy and cast steel (less 930 275 7

than 5% of alloying elements) Quenched and 1000 300 8 70-120 0.15-0.30

tempered

1200 350 9

Annealed 680 200 10 80-150 0.10-0.25

High alloyed steel, cast Quenched and

steel and tool steel 1100 325 11 70-120 0.10-0.25

tempered

Ferritic / pearlitic 180 15

Grey cast iron (GG) Pearlitic / 180-300 0.18-0.35

martensitic 260 16

K Ferritic 160 17

Nodular cast iron (GGG) 0.15-0.30

Pearlitic 250 18 150-250

Ferritic 130 19

Malleable cast iron 0.15-0.35

Pearlitic 230 20

MD-DFN Cutting Parameters

Feed Vs. Drill

Tensile Diameter

ISO Material Condition Strength Rm Hardness HB Material No. Vc [m/min] 33<ØD<40 (mm)

2

f [mm/rev]

[N/mm ]

< 0.25 %C Annealed 420 125 1 80-110-140

≥ 0.25 %C Annealed 650 190 2 90-105-130

Non-alloy steel < 0.55 %C Quenched and 850 250 3 80-100-120

and cast steel, tempered 0.30 0.40 0.50

free cutting steel Annealed 750 220 4 70-90-110

≥ 0.55 %C Quenched and

tempered 1000 300 5 50-70-90

P

Annealed 600 200 6 80-100-120

Low alloy and cast steel (less 930 275 7 70-90-110 0.30 0.40 0.50

than 5% of alloying elements) Quenched and 1000 300 8 50-70-90

tempered

1200 350 9 40-55-70

Annealed 680 200 10 50-70-90

High alloyed steel, cast 0.25 0.30 0.35

steel and tool steel Quenched and 1100 325 11 40-60-80

tempered

Ferritic / pearlitic 180 15 90-125-160

Grey cast iron (GG) Pearlitic /

martensitic 260 16 80-110-140

K Ferritic 160 17 90-135-180 0.40 0.50 0.60

Nodular cast iron (GGG)

Pearlitic 250 18 80-110-140

Ferritic 130 19 90-125-160

Malleable cast iron

Pearlitic 230 20 80-110-140

85