Page 185 - ISCAR(MILLINGCATALOG 38_2021)

P. 185

USER GUIDE

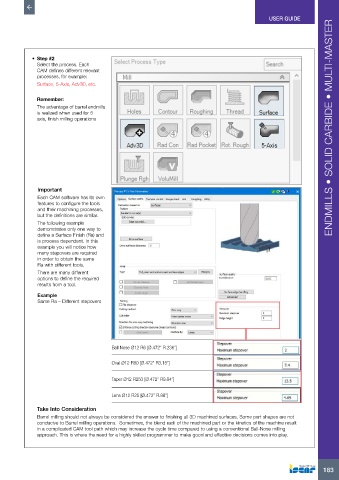

• Step #2

Select the process. Each

CAM defines different relevant

processes, for example:

Surface, 5-Axis, Adv3D, etc.

Remember:

The advantage of barrel endmills

is realized when used for 5

axis, finish milling operations ENDMILLS • SOLID CARBIDE • MULTI-MASTER

Important

Each CAM software has its own

features to configure the tools

and their machining processes,

but the definitions are similar.

The following example

demonstrates only one way to

define a Surface Finish (Ra) and

is process dependent. In this

example you will notice how

many stepovers are required

in order to obtain the same

Ra with different tools.

There are many different

options to define the required

results from a tool.

Example

Same Ra – Different stepovers

Ball Nose Ø12 R6 [Ø.472” R.236”]

Oval Ø12 R80 [Ø.472” R3.15”]

Taper Ø12 R250 [Ø.472” R9.84”]

Lens Ø12 R25 [Ø.472” R.98”]

Take Into Consideration

Barrel milling should not always be considered the answer to finishing all 3D machined surfaces. Some part shapes are not

conducive to Barrel milling operations. Sometimes, the blend radii of the machined part or the kinetics of the machine result

in a complicated CAM tool path which may increase the cycle time compared to using a conventional Ball-Nose milling

approach. This is where the need for a highly skilled programmer to make good and effective decisions comes into play.

183