Page 144 - ISCAR(TURNING-CATALOG-42-2022)

P. 144

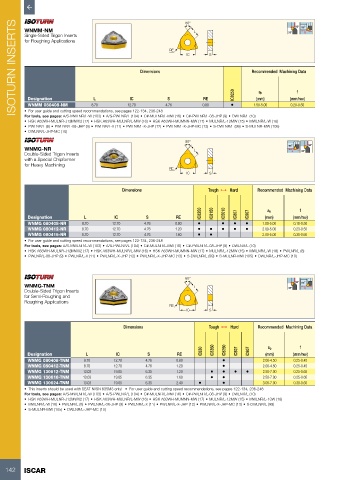

ISOTURN INSERTS WNMM-NM Dimensions RE 80° L S Recommended Machining Data

95°

95 º

95°

Single-Sided Trigon Inserts

for Roughing Applications

IC

f

IC8250

ap

RE

Designation

IC

L

S

(mm)

•

12.70

8.70

4.76

0.80

WNMM 080408-NM

0.20-0.50

1.50-5.00

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A/S-MWLNR/L-W (103) • A/S-PWLNR/L (104) • C#-MULNR/L-MW (16) • C#-PWLNR/L-08-JHP (9) • DWLNR/L (10)

• HSK A63WH-MULNR-J12MWX2 (17) • HSK A63WH-MULNR/L-MW (16) • HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • MWLNR/L-W (18) (mm/rev)

• PWLNR/L (8) • PWLNR/L-08-JHP (9) • PWLNR/L-X (11) • PWLNR/L-X-JHP (12) • PWLNR/L-X-JHP-MC (13) • S-DWLNR/L (99) • S-MULNR-MW (105)

• DWLNR/L-JHP-MC (10)

80°

WNMG-NR L 95 º 95° 95°

Double-Sided Trigon Inserts

with a Special Chipformer

for Heavy Machining

RE

IC S

Dimensions Tough 1 Hard Recommended Machining Data

IC8250 IC8150 IC5010 IC807 IC907 ap f

Designation L IC S RE (mm) (mm/rev)

WNMG 080408-NR 8.70 12.70 4.76 0.80 • • • • 1.00-5.00 0.18-0.50

WNMG 080412-NR 8.70 12.70 4.76 1.20 • • • • • 2.00-5.00 0.23-0.55

WNMG 080416-NR 8.70 12.70 4.76 1.60 • • 2.00-5.00 0.30-0.60

• For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A/S-MWLNR/L-W (103) • A/S-PWLNR/L (104) • C#-MULNR/L-MW (16) • C#-PWLNR/L-08-JHP (9) • DWLNR/L (10)

• HSK A63WH-MULNR-J12MWX2 (17) • HSK A63WH-MULNR/L-MW (16) • HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • MWLNR/L-W (18) • PWLNR/L (8)

• PWLNR/L-08-JHP (9) • PWLNR/L-X (11) • PWLNR/L-X-JHP (12) • PWLNR/L-X-JHP-MC (13) • S-DWLNR/L (99) • S-MULNR-MW (105) • DWLNR/L-JHP-MC (10)

80°

WNMG-TNM L 95° 95° 95 º

Double-Sided Trigon Inserts

for Semi-Roughing and

Roughing Applications

RE

IC S

Dimensions Tough 1 Hard Recommended Machining Data

IC830 IC8350 IC8250 IC807 IC907 ap f

Designation L IC S RE (mm) (mm/rev)

WNMG 080408-TNM 8.70 12.70 4.76 0.80 • 2.00-4.50 0.25-0.45

WNMG 080412-TNM 8.70 12.70 4.76 1.20 • 2.00-4.50 0.25-0.45

WNMG 130612-TNM 13.03 19.05 6.35 1.20 • • • • 2.50-7.00 0.25-0.65

WNMG 130616-TNM 13.03 19.05 6.35 1.60 • • 2.50-7.00 0.25-0.65

WNMG 130624-TNM 13.03 19.05 6.35 2.40 • • 3.00-7.00 0.30-0.65

• This inserts should be used with SEAT IWSN 635M3 only! • For user guide and cutting speed recommendations, see pages 122-134, 236-248

For tools, see pages: A/S-MWLNR/L-W (103) • A/S-PWLNR/L (104) • C#-MULNR/L-MW (16) • C#-PWLNR/L-08-JHP (9) • DWLNR/L (10)

• HSK A63WH-MULNR-J12MWX2 (17) • HSK A63WH-MULNR/L-MW (16) • HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • MWLNR/L-13W (18)

• MWLNR/L-W (18) • PWLNR/L (8) • PWLNR/L-08-JHP (9) • PWLNR/L-X (11) • PWLNR/L-X-JHP (12) • PWLNR/L-X-JHP-MC (13) • S-DWLNR/L (99)

• S-MULNR-MW (105) • DWLNR/L-JHP-MC (10)

142 ISCAR