Page 253 - ISCAR(TURNING-CATALOG-42-2022)

P. 253

USER GUIDE

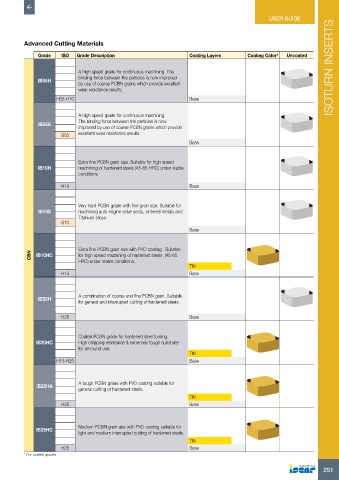

ISOTURN INSERTS

Advanced Cutting Materials

Grade ISO Grade Description Coating Layers Coating Color* Uncoated

A high speed grade for continuous machining. The

binding force between the particles is now improved

IB05H

by use of coarse PCBN grains which provide excellent

wear resistance results.

H05-H10 Base

A high speed grade for continuous machining.

The binding force between the particles is now

IB05S

improved by use of coarse PCBN grains which provide

S05 excellent wear resistance results.

Base

Extra fine PCBN grain size. Suitable for high speed

IB10H machining of hardened steels (45-65 HRC) under stable

conditions.

H10 Base

Very hard PCBN grade with fine grain size. Suitable for

IB10S machining auto engine valve seats, sintered metals and

Titanium alloys.

S10

Base

Extra fine PCBN grain size with PVD coating. Suitable

CBN IB10HC for high speed machining of hardened steels (45-65

HRC) under stable conditions.

TiN

H10 Base

IB20H A combination of coarse and fine PCBN grain. Suitable

for general and interrupted cutting of hardened steels.

H20 Base

Coated PCBN grade for hardened steel turning.

IB20HC High chipping resistance & extremely tough substrate

for all-round use.

TiN

H15-H25 Base

A tough PCBN grade with PVD coating suitable for

IB25HA

general cutting of hardened steels.

TiN

H25 Base

Medium PCBN grain size with PVD coating suitable for

IB25HC

light and medium interrupted cutting of hardened steels.

TiN

H25 Base

* For coated grades

251