Page 254 - ISCAR(TURNING-CATALOG-42-2022)

P. 254

USER GUIDE

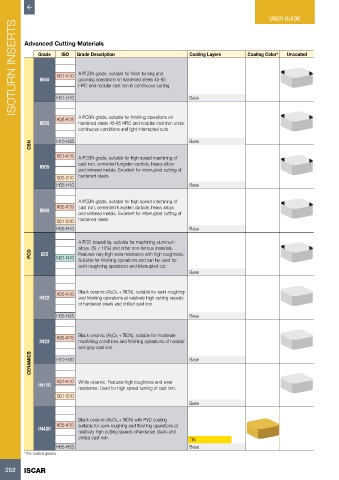

ISOTURN INSERTS Advanced Cutting Materials Coating Layers Coating Color* Uncoated

ISO

Grade

Grade Description

A PCBN grade, suitable for finish turning and

K01-K10

IB50

grooving operations on hardened steels 45-65

HRC and nodular cast iron in continuous cutting.

H01-H10

K05-K15 A PCBN grade, suitable for finishing operations on Base

IB55 hardened steels 45-65 HRC and nodular cast iron under

continuous conditions and light interrupted cuts.

CBN H10-H25 Base

K01-K15 A PCBN grade, suitable for high speed machining of

cast iron, cemented tungsten carbide, heavy alloys

IB85

and sintered metals. Excellent for interrupted cutting of

S05-S10 hardened steels.

H05-H10 Base

A PCBN grade, suitable for high speed machining of

K05-K15 cast iron, cemented tungsten carbide, heavy alloys

IB90

and sintered metals. Excellent for interrupted cutting of

S01-S10 hardened steels.

H05-H10 Base

A PCD brazed tip, suitable for machining aluminum

alloys (Si < 12%) and other non-ferrous materials.

PCD ID5 N01-N10 Features very high wear resistance with high toughness.

Suitable for finishing operations and can be used for

semi roughning operations and interrupted cut.

Base

K05-K10 Black ceramic (Al2O3 + TiCN), suitable for semi-roughing

IN22 and finishing operations at relatively high cutting speeds

of hardened steels and chilled cast iron.

H05-H25 Base

K05-K15 Black ceramic (Al2O3 + TiCN), suitable for moderate

IN23 machining conditions and finishing operations of nodular

and gray cast iron.

CERAMICS H10-H30 Base

K01-K10 White ceramic. Features high toughness and wear

IN110

resistance. Used for high speed turning of cast iron.

S01-S10

Base

Black ceramic (Al2O3 + TiCN) with PVD coating

K05-K10 suitable for semi-roughing and finishing operations at

IN420

relatively high cutting speeds ofhardened steels and

chilled cast iron. TiN

H05-H25 Base

* For coated grades

252 ISCAR