Page 100 - 21-036 APPLITEC catalogue.indb

P. 100

a p

a e

f z

d 1

v c

n

v f

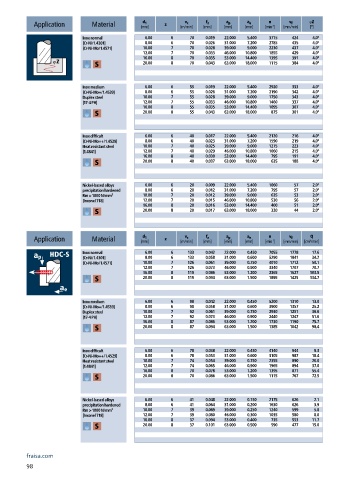

Application Material [mm] z [m/min] [mm] [mm] [mm] [min ] -1 [mm/min] jZ

[°]

Inox normal 6.00 6 70 0.019 22.000 5.400 3715 424 4.0°

[Cr-Ni/1.4301] 8.00 6 70 0.026 31.000 7.200 2785 435 4.0°

[Cr-Ni-Mo/1.4571] 10.00 7 70 0.028 39.000 9.000 2230 437 4.0°

12.00 7 70 0.033 46.000 10.800 1855 429 4.0°

16.00 8 70 0.035 53.000 14.400 1395 391 4.0°

S 20.00 8 70 0.043 63.000 18.000 1115 384 4.0°

Inox medium 6.00 6 55 0.019 22.000 5.400 2920 333 4.0°

[Cr-Ni-Mo+/1.4539] 8.00 6 55 0.026 31.000 7.200 2190 342 4.0°

Duplex steel 10.00 7 55 0.028 39.000 9.000 1750 343 4.0°

[17-4 PH] 12.00 7 55 0.033 46.000 10.800 1460 337 4.0°

16.00 8 55 0.035 53.000 14.400 1095 307 4.0°

S 20.00 8 55 0.043 63.000 18.000 875 301 4.0°

Inox difficult 6.00 6 40 0.017 22.000 5.400 2120 216 4.0°

[Cr-Ni-Mo++/1.4529] 8.00 6 40 0.023 31.000 7.200 1590 219 4.0°

Heat resistant steel 10.00 7 40 0.025 39.000 9.000 1275 223 4.0°

[1.4841] 12.00 7 40 0.029 46.000 10.800 1060 215 4.0°

16.00 8 40 0.030 53.000 14.400 795 191 4.0°

S 20.00 8 40 0.037 63.000 18.000 635 188 4.0°

Nickel-based alloys 6.00 6 20 0.009 22.000 5.400 1060 57 2.0°

precipitation hardened 8.00 6 20 0.012 31.000 7.200 795 57 2.0°

Rm > 1000 N/mm² 10.00 7 20 0.012 39.000 9.000 635 53 2.0°

[Inconel 718] 12.00 7 20 0.015 46.000 10.800 530 56 2.0°

16.00 8 20 0.016 53.000 14.400 400 51 2.0°

S 20.00 8 20 0.017 63.000 18.000 320 44 2.0°

Q

a e

f z

v c

d 1

v f

n

a p

Application Material [mm] z [m/min] [mm] [mm] [mm] [min ] -1 [mm/min] [cm /min]

3

Inox normal 6.00 6 133 0.042 22.000 0.450 7055 1778 17.6

[Cr-Ni/1.4301] 8.00 6 133 0.058 31.000 0.600 5290 1841 34.2

[Cr-Ni-Mo/1.4571] 10.00 7 126 0.061 39.000 0.750 4010 1712 50.1

12.00 7 126 0.073 46.000 0.900 3340 1707 70.7

16.00 8 119 0.086 53.000 1.200 2365 1627 103.5

S 20.00 8 119 0.094 63.000 1.500 1895 1425 134.7

Inox medium 6.00 6 98 0.042 22.000 0.450 5200 1310 13.0

[Cr-Ni-Mo+/1.4539] 8.00 6 98 0.058 31.000 0.600 3900 1357 25.2

Duplex steel 10.00 7 92 0.061 39.000 0.750 2930 1251 36.6

[17-4 PH] 12.00 7 92 0.073 46.000 0.900 2440 1247 51.6

16.00 8 87 0.086 53.000 1.200 1730 1190 75.7

S 20.00 8 87 0.094 63.000 1.500 1385 1042 98.4

Inox difficult 6.00 6 78 0.038 22.000 0.450 4140 944 9.3

[Cr-Ni-Mo++/1.4529] 8.00 6 78 0.053 31.000 0.600 3105 987 18.4

Heat resistant steel 10.00 7 74 0.054 39.000 0.750 2355 890 26.0

[1.4841] 12.00 7 74 0.065 46.000 0.900 1965 894 37.0

16.00 8 70 0.078 53.000 1.200 1395 871 55.4

S 20.00 8 70 0.086 63.000 1.500 1115 767 72.5

Nickel-based alloys 6.00 6 41 0.048 22.000 0.150 2175 626 2.1

precipitation hardened 8.00 6 41 0.064 31.000 0.200 1630 626 3.9

Rm > 1000 N/mm² 10.00 7 39 0.069 39.000 0.250 1240 599 5.8

[Inconel 718] 12.00 7 39 0.080 46.000 0.300 1035 580 8.0

16.00 8 37 0.094 53.000 0.400 735 553 11.7

S 20.00 8 37 0.101 63.000 0.500 590 477 15.0

fraisa.com

98