Page 48 - 21-036 APPLITEC catalogue.indb

P. 48

a p

a e

f z

d 1

v c

n

v f

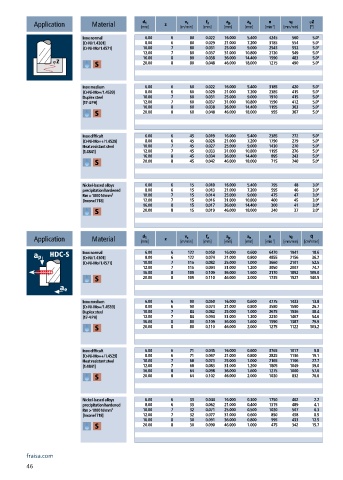

Application Material [mm] z [m/min] [mm] [mm] [mm] [min ] -1 [mm/min] jZ

[°]

Inox normal 6.00 6 80 0.022 16.000 5.400 4245 560 5.0°

[Cr-Ni/1.4301] 8.00 6 80 0.029 21.000 7.200 3185 554 5.0°

[Cr-Ni-Mo/1.4571] 10.00 7 80 0.031 25.000 9.000 2545 552 5.0°

12.00 7 80 0.037 31.000 10.800 2120 549 5.0°

16.00 8 80 0.038 36.000 14.400 1590 483 5.0°

S 20.00 8 80 0.048 46.000 18.000 1275 490 5.0°

Inox medium 6.00 6 60 0.022 16.000 5.400 3185 420 5.0°

[Cr-Ni-Mo+/1.4539] 8.00 6 60 0.029 21.000 7.200 2385 415 5.0°

Duplex steel 10.00 7 60 0.031 25.000 9.000 1910 415 5.0°

[17-4 PH] 12.00 7 60 0.037 31.000 10.800 1590 412 5.0°

16.00 8 60 0.038 36.000 14.400 1195 363 5.0°

S 20.00 8 60 0.048 46.000 18.000 955 367 5.0°

Inox difficult 6.00 6 45 0.019 16.000 5.400 2385 272 5.0°

[Cr-Ni-Mo++/1.4529] 8.00 6 45 0.026 21.000 7.200 1790 279 5.0°

Heat resistant steel 10.00 7 45 0.027 25.000 9.000 1430 270 5.0°

[1.4841] 12.00 7 45 0.033 31.000 10.800 1195 276 5.0°

16.00 8 45 0.034 36.000 14.400 895 243 5.0°

S 20.00 8 45 0.042 46.000 18.000 715 240 5.0°

Nickel-based alloys 6.00 6 15 0.010 16.000 5.400 795 48 3.0°

precipitation hardened 8.00 6 15 0.013 21.000 7.200 595 46 3.0°

Rm > 1000 N/mm² 10.00 7 15 0.014 25.000 9.000 475 47 3.0°

[Inconel 718] 12.00 7 15 0.016 31.000 10.800 400 45 3.0°

16.00 8 15 0.017 36.000 14.400 300 41 3.0°

S 20.00 8 15 0.019 46.000 18.000 240 37 3.0°

Q

a e

f z

v c

d 1

v f

n

a p

Application Material [mm] z [m/min] [mm] [mm] [mm] [min ] -1 [mm/min] [cm /min]

3

Inox normal 6.00 6 122 0.050 16.000 0.600 6470 1941 18.6

[Cr-Ni/1.4301] 8.00 6 122 0.074 21.000 0.800 4855 2156 36.2

[Cr-Ni-Mo/1.4571] 10.00 7 115 0.082 25.000 1.000 3660 2101 52.5

12.00 7 115 0.094 31.000 1.200 3050 2007 74.7

16.00 8 109 0.109 36.000 1.600 2170 1892 109.0

S 20.00 8 109 0.110 46.000 2.000 1735 1527 140.5

Inox medium 6.00 6 90 0.050 16.000 0.600 4775 1433 13.8

[Cr-Ni-Mo+/1.4539] 8.00 6 90 0.074 21.000 0.800 3580 1590 26.7

Duplex steel 10.00 7 84 0.082 25.000 1.000 2675 1536 38.4

[17-4 PH] 12.00 7 84 0.094 31.000 1.200 2230 1467 54.6

16.00 8 80 0.109 36.000 1.600 1590 1387 79.9

S 20.00 8 80 0.110 46.000 2.000 1275 1122 103.2

Inox difficult 6.00 6 71 0.045 16.000 0.600 3765 1017 9.8

[Cr-Ni-Mo++/1.4529] 8.00 6 71 0.067 21.000 0.800 2825 1136 19.1

Heat resistant steel 10.00 7 68 0.073 25.000 1.000 2165 1106 27.7

[1.4841] 12.00 7 68 0.083 31.000 1.200 1805 1049 39.0

16.00 8 64 0.098 36.000 1.600 1275 1000 57.6

S 20.00 8 64 0.102 46.000 2.000 1020 832 76.6

Nickel-based alloys 6.00 6 33 0.044 16.000 0.300 1750 462 2.2

precipitation hardened 8.00 6 33 0.062 21.000 0.400 1315 489 4.1

Rm > 1000 N/mm² 10.00 7 32 0.071 25.000 0.500 1020 507 6.3

[Inconel 718] 12.00 7 32 0.077 31.000 0.600 850 458 8.5

16.00 8 30 0.091 36.000 0.800 595 433 12.5

S 20.00 8 30 0.090 46.000 1.000 475 342 15.7

fraisa.com

46