Page 844 - 21-036 APPLITEC catalogue.indb

P. 844

Information for cutting data

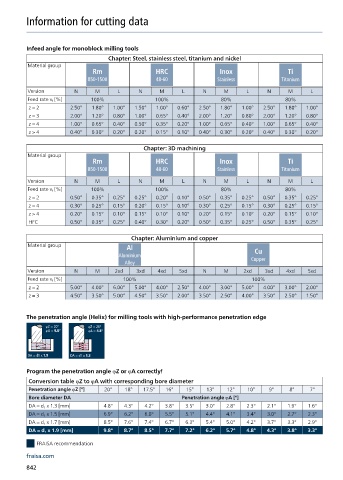

Infeed angle for monoblock milling tools

Chapter: Steel, stainless steel, titanium and nickel

Material group

Rm HRC Inox Ti

850-1500 48-60 Stainless Titanium

Version N M L N M L N M L N M L

Feed rate v f [%] 100% 100% 80% 80%

z = 2 2.50° 1.80° 1.00° 1.50° 1.00° 0.60° 2.50° 1.80° 1.00° 2.50° 1.80° 1.00°

z = 3 2.00° 1.20° 0.80° 1.00° 0.65° 0.40° 2.00° 1.20° 0.80° 2.00° 1.20° 0.80°

z = 4 1.00° 0.65° 0.40° 0.50° 0.35° 0.20° 1.00° 0.65° 0.40° 1.00° 0.65° 0.40°

z > 4 0.40° 0.30° 0.20° 0.20° 0.15° 0.10° 0.40° 0.30° 0.20° 0.40° 0.30° 0.20°

Chapter: 3D machining

Material group

Rm HRC Inox Ti

850-1500 48-60 Stainless Titanium

Version N M L N M L N M L N M L

Feed rate v f [%] 100% 100% 80% 80%

z = 2 0.50° 0.35° 0.25° 0.25° 0.20° 0.10° 0.50° 0.35° 0.25° 0.50° 0.35° 0.25°

z = 4 0.30° 0.25° 0.15° 0.20° 0.15° 0.10° 0.30° 0.25° 0.15° 0.30° 0.25° 0.15°

z > 4 0.20° 0.15° 0.10° 0.15° 0.10° 0.10° 0.20° 0.15° 0.10° 0.20° 0.15° 0.10°

HFC 0.50° 0.35° 0.25° 0.40° 0.30° 0.20° 0.50° 0.35° 0.25° 0.50° 0.35° 0.25°

Chapter: Aluminium and copper

Material group Al

Cu

Aluminium Copper

Alloy

Version N M 2xd 3xd 4xd 5xd N M 2xd 3xd 4xd 5xd

Feed rate v f [%] 100% 100%

z = 2 5.00° 4.00° 6.00° 5.00° 4.00° 2.50° 4.00° 3.00° 5.00° 4.00° 3.00° 2.00°

z = 3 4.50° 3.50° 5.00° 4.50° 3.50° 2.00° 3.50° 2.50° 4.00° 3.50° 2.50° 1.50°

The penetration angle (Helix) for milling tools with high-performance penetration edge

Program the penetration angle jZ or jA correctly!

Conversion table jZ to jA with corresponding bore diameter

Penetration angle jZ [°] 20° 18° 17.5° 16° 15° 13° 12° 10° 9° 8° 7°

Bore diameter DA Penetration angle jA [°]

DA = d 1 x 1.3 [mm] 4.8° 4.3° 4.2° 3.8° 3.5° 3.0° 2.8° 2.3° 2.1° 1.9° 1.6°

DA = d 1 x 1.5 [mm] 6.9° 6.2° 6.0° 5.5° 5.1° 4.4° 4.1° 3.4° 3.0° 2.7° 2.3°

DA = d 1 x 1.7 [mm] 8.5° 7.6° 7.4° 6.7° 6.3° 5.4° 5.0° 4.2° 3.7° 3.3° 2.9°

DA = d 1 x 1.9 [mm] 9.8° 8.7° 8.5° 7.7° 7.2° 6.2° 5.7° 4.8° 4.3° 3.8° 3.3°

FRAISA recommendation

fraisa.com

842