Page 140 - Carbide drills I Thread cutting tools 2023

P. 140

f z

n

P

v c

v f

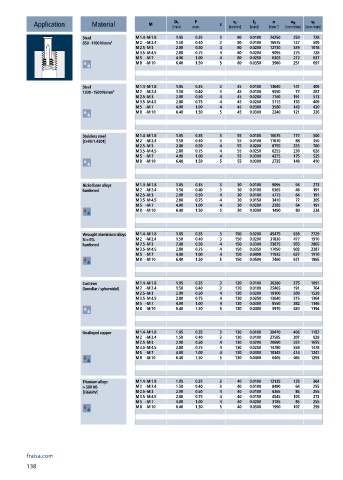

Application Material M [mm] max. z [m/min] [mm] [min ] -1 [mm/min] [mm/min]

v fc

D 1

Steel M 1.4 - M 1.8 1.05 0.35 3 80 0.0100 24250 250 728

850 - 1100 N/mm² M 2 - M 2.4 1.50 0.40 3 80 0.0100 16975 127 509

M 2.5 - M 3 2.00 0.50 4 80 0.0200 12730 339 1018

M 3.5 - M 4.5 2.80 0.75 4 80 0.0200 9095 275 728

M 5 - M 7 4.00 1.00 4 80 0.0250 6365 212 637

M 8 - M 10 6.40 1.50 5 80 0.0350 3980 251 697

Steel M 1.4 - M 1.8 1.05 0.35 3 45 0.0100 13640 141 409

1300 - 1500 N/mm² M 2 - M 2.4 1.50 0.40 3 45 0.0100 9550 72 287

M 2.5 - M 3 2.00 0.50 4 45 0.0200 7160 191 573

M 3.5 - M 4.5 2.80 0.75 4 45 0.0200 5115 155 409

M 5 - M 7 4.00 1.00 4 45 0.0300 3580 143 430

M 8 - M 10 6.40 1.50 5 45 0.0300 2240 121 336

Stainless steel M 1.4 - M 1.8 1.05 0.35 3 55 0.0100 16675 172 500

[Cr-Ni/1.4301] M 2 - M 2.4 1.50 0.40 3 55 0.0100 11670 88 350

M 2.5 - M 3 2.00 0.50 4 55 0.0200 8755 233 700

M 3.5 - M 4.5 2.80 0.75 4 55 0.0250 6255 236 626

M 5 - M 7 4.00 1.00 4 55 0.0300 4375 175 525

M 8 - M 10 6.40 1.50 5 55 0.0300 2735 148 410

Nickel base alloys M 1.4 - M 1.8 1.05 0.35 3 30 0.0100 9095 94 273

hardened M 2 - M 2.4 1.50 0.40 3 30 0.0100 6365 48 191

M 2.5 - M 3 2.00 0.50 4 30 0.0100 4775 64 191

M 3.5 - M 4.5 2.80 0.75 4 30 0.0150 3410 77 205

M 5 - M 7 4.00 1.00 4 30 0.0200 2385 64 191

M 8 - M 10 6.40 1.50 5 30 0.0300 1490 80 224

Wrought aluminium alloys M 1.4 - M 1.8 1.05 0.35 3 150 0.0200 45475 938 2729

Si < 6% M 2 - M 2.4 1.50 0.40 3 150 0.0200 31830 477 1910

hardened M 2.5 - M 3 2.00 0.50 4 150 0.0300 23875 955 2865

M 3.5 - M 4.5 2.80 0.75 4 150 0.0350 17050 902 2387

M 5 - M 7 4.00 1.00 4 150 0.0400 11935 637 1910

M 8 - M 10 6.40 1.50 5 150 0.0500 7460 671 1865

Cast iron M 1.4 - M 1.8 1.05 0.35 3 120 0.0100 36380 375 1091

(lamellar / spheroidal) M 2 - M 2.4 1.50 0.40 3 120 0.0100 25465 191 764

M 2.5 - M 3 2.00 0.50 4 120 0.0200 19100 509 1528

M 3.5 - M 4.5 2.80 0.75 4 120 0.0250 13640 515 1364

M 5 - M 7 4.00 1.00 4 120 0.0300 9550 382 1146

M 8 - M 10 6.40 1.50 5 120 0.0400 5970 430 1194

Unalloyed copper M 1.4 - M 1.8 1.05 0.35 3 130 0.0100 39410 406 1182

M 2 - M 2.4 1.50 0.40 3 130 0.0100 27585 207 828

M 2.5 - M 3 2.00 0.50 4 130 0.0200 20690 552 1655

M 3.5 - M 4.5 2.80 0.75 4 130 0.0250 14780 558 1478

M 5 - M 7 4.00 1.00 4 130 0.0300 10345 414 1241

M 8 - M 10 6.40 1.50 5 130 0.0400 6465 465 1293

Titanium alloys M 1.4 - M 1.8 1.05 0.35 3 40 0.0100 12125 125 364

> 300 HB M 2 - M 2.4 1.50 0.40 3 40 0.0100 8490 64 255

[Ti6Al4V] M 2.5 - M 3 2.00 0.50 4 40 0.0100 6365 85 255

M 3.5 - M 4.5 2.80 0.75 4 40 0.0150 4545 103 273

M 5 - M 7 4.00 1.00 4 40 0.0200 3185 85 255

M 8 - M 10 6.40 1.50 5 40 0.0300 1990 107 299

fraisa.com

138