Page 142 - Carbide drills I Thread cutting tools 2023

P. 142

f z

n

v c

P

v f

v fc

D 1

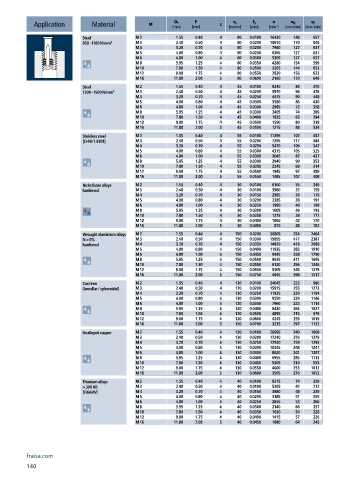

Application Material M [mm] [mm] z [m/min] [mm] [min ] -1 [mm/min] [mm/min]

Steel M 2 1.55 0.40 4 80 0.0100 16430 148 657

850 - 1100 N/mm² M 3 2.40 0.50 4 80 0.0200 10610 170 849

M 4 3.20 0.70 4 80 0.0200 7960 127 637

M 5 4.00 0.80 4 80 0.0250 6365 127 637

M 6 4.80 1.00 4 80 0.0300 5305 127 637

M 8 5.95 1.25 4 80 0.0350 4280 154 599

M 10 7.80 1.50 4 80 0.0500 3265 144 653

M 12 9.00 1.75 4 80 0.0550 2830 156 623

M 16 11.80 2.00 5 80 0.0600 2160 170 648

Steel M 2 1.55 0.40 4 45 0.0100 9240 83 370

1300 - 1500 N/mm² M 3 2.40 0.50 4 45 0.0200 5970 96 478

M 4 3.20 0.70 4 45 0.0250 4475 90 448

M 5 4.00 0.80 4 45 0.0300 3580 86 430

M 6 4.80 1.00 4 45 0.0300 2985 72 358

M 8 5.95 1.25 4 45 0.0300 2405 74 289

M 10 7.80 1.50 4 45 0.0400 1835 65 294

M 12 9.00 1.75 4 45 0.0500 1590 80 318

M 16 11.80 2.00 5 45 0.0550 1215 88 334

Stainless steel M 2 1.55 0.40 4 55 0.0100 11295 102 452

[Cr-Ni/1.4301] M 3 2.40 0.50 4 55 0.0200 7295 117 584

M 4 3.20 0.70 4 55 0.0250 5470 109 547

M 5 4.00 0.80 4 55 0.0300 4375 105 525

M 6 4.80 1.00 4 55 0.0300 3645 87 437

M 8 5.95 1.25 4 55 0.0300 2940 90 353

M 10 7.80 1.50 4 55 0.0350 2245 69 314

M 12 9.00 1.75 4 55 0.0500 1945 97 389

M 16 11.80 2.00 5 55 0.0550 1485 107 408

Nickel base alloys M 2 1.55 0.40 4 30 0.0100 6160 55 246

hardened M 3 2.40 0.50 4 30 0.0100 3980 32 159

M 4 3.20 0.70 4 30 0.0150 2985 36 179

M 5 4.00 0.80 4 30 0.0200 2385 38 191

M 6 4.80 1.00 4 30 0.0250 1990 40 199

M 8 5.95 1.25 4 30 0.0300 1605 49 193

M 10 7.80 1.50 4 30 0.0350 1225 38 172

M 12 9.00 1.75 4 30 0.0400 1060 42 170

M 16 11.80 2.00 5 30 0.0450 810 48 182

Wrought aluminium alloys M 2 1.55 0.40 4 150 0.0200 30805 554 2464

Si < 6% M 3 2.40 0.50 4 150 0.0300 19895 477 2387

hardened M 4 3.20 0.70 4 150 0.0350 14920 418 2089

M 5 4.00 0.80 4 150 0.0400 11935 382 1910

M 6 4.80 1.00 4 150 0.0450 9945 358 1790

M 8 5.95 1.25 4 150 0.0500 8025 411 1605

M 10 7.80 1.50 4 150 0.0550 6120 296 1346

M 12 9.00 1.75 4 150 0.0650 5305 345 1379

M 16 11.80 2.00 5 150 0.0750 4045 398 1517

Cast iron M 2 1.55 0.40 4 120 0.0100 24645 222 986

(lamellar / spheroidal) M 3 2.40 0.50 4 120 0.0200 15915 255 1273

M 4 3.20 0.70 4 120 0.0250 11935 239 1194

M 5 4.00 0.80 4 120 0.0300 9550 229 1146

M 6 4.80 1.00 4 120 0.0350 7960 223 1114

M 8 5.95 1.25 4 120 0.0400 6420 263 1027

M 10 7.80 1.50 4 120 0.0500 4895 215 979

M 12 9.00 1.75 4 120 0.0600 4245 255 1019

M 16 11.80 2.00 5 120 0.0700 3235 297 1132

Unalloyed copper M 2 1.55 0.40 4 130 0.0100 26695 240 1068

M 3 2.40 0.50 4 130 0.0200 17240 276 1379

M 4 3.20 0.70 4 130 0.0250 12930 259 1293

M 5 4.00 0.80 4 130 0.0300 10345 248 1241

M 6 4.80 1.00 4 130 0.0350 8620 241 1207

M 8 5.95 1.25 4 130 0.0400 6955 285 1113

M 10 7.80 1.50 4 130 0.0450 5305 210 955

M 12 9.00 1.75 4 130 0.0550 4600 253 1012

M 16 11.80 2.00 5 130 0.0600 3505 276 1052

Titanium alloys M 2 1.55 0.40 4 40 0.0100 8215 74 329

> 300 HB M 3 2.40 0.50 4 40 0.0100 5305 42 212

[Ti6Al4V] M 4 3.20 0.70 4 40 0.0150 3980 48 239

M 5 4.00 0.80 4 40 0.0200 3185 51 255

M 6 4.80 1.00 4 40 0.0250 2655 53 266

M 8 5.95 1.25 4 40 0.0300 2140 66 257

M 10 7.80 1.50 4 40 0.0350 1630 50 228

M 12 9.00 1.75 4 40 0.0400 1415 57 226

M 16 11.80 2.00 5 40 0.0450 1080 64 243

fraisa.com

140