Page 146 - Carbide drills I Thread cutting tools 2023

P. 146

n

f z

v c

v f

v fc

D 1

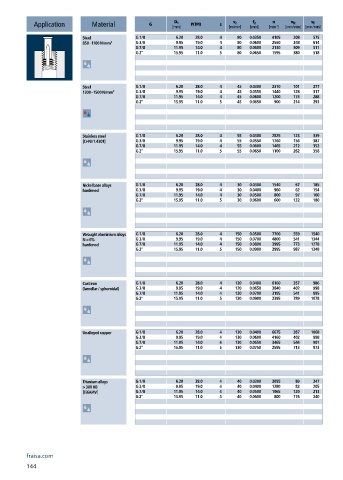

Application Material G [mm] P(TPI) z [m/min] [mm] [min ] -1 [mm/min] [mm/min]

Steel G 1/8 6.20 28.0 4 80 0.0350 4105 208 575

850 - 1100 N/mm² G 3/8 9.95 19.0 4 80 0.0600 2560 248 614

G 7/8 11.95 14.0 4 80 0.0600 2130 309 511

G 2‘‘ 15.95 11.0 5 80 0.0650 1595 380 518

Steel G 1/8 6.20 28.0 4 45 0.0300 2310 101 277

1300 - 1500 N/mm² G 3/8 9.95 19.0 4 45 0.0550 1440 128 317

G 7/8 11.95 14.0 4 45 0.0600 1200 174 288

G 2‘‘ 15.95 11.0 5 45 0.0650 900 214 293

Stainless steel G 1/8 6.20 28.0 4 55 0.0300 2825 123 339

[Cr-Ni/1.4301] G 3/8 9.95 19.0 4 55 0.0550 1760 156 387

G 7/8 11.95 14.0 4 55 0.0600 1465 212 352

G 2‘‘ 15.95 11.0 5 55 0.0650 1100 262 358

Nickel base alloys G 1/8 6.20 28.0 4 30 0.0300 1540 67 185

hardened G 3/8 9.95 19.0 4 30 0.0400 960 62 154

G 7/8 11.95 14.0 4 30 0.0500 800 97 160

G 2‘‘ 15.95 11.0 5 30 0.0600 600 132 180

Wrought aluminium alloys G 1/8 6.20 28.0 4 150 0.0500 7700 559 1540

Si < 6% G 3/8 9.95 19.0 4 150 0.0700 4800 541 1344

hardened G 7/8 11.95 14.0 4 150 0.0800 3995 773 1278

G 2‘‘ 15.95 11.0 5 150 0.0900 2995 987 1348

Cast iron G 1/8 6.20 28.0 4 120 0.0400 6160 357 986

(lamellar / spheroidal) G 3/8 9.95 19.0 4 120 0.0650 3840 402 998

G 7/8 11.95 14.0 4 120 0.0700 3195 541 895

G 2‘‘ 15.95 11.0 5 120 0.0900 2395 789 1078

Unalloyed copper G 1/8 6.20 28.0 4 130 0.0400 6675 387 1068

G 3/8 9.95 19.0 4 130 0.0600 4160 402 998

G 7/8 11.95 14.0 4 130 0.0650 3465 544 901

G 2‘‘ 15.95 11.0 5 130 0.0750 2595 713 973

Titanium alloys G 1/8 6.20 28.0 4 40 0.0300 2055 89 247

> 300 HB G 3/8 9.95 19.0 4 40 0.0400 1280 83 205

[Ti6Al4V] G 7/8 11.95 14.0 4 40 0.0500 1065 129 213

G 2‘‘ 15.95 11.0 5 40 0.0600 800 176 240

fraisa.com

144