Page 150 - Carbide drills I Thread cutting tools 2023

P. 150

f z

n

P

v c

v f

v fc

D 1

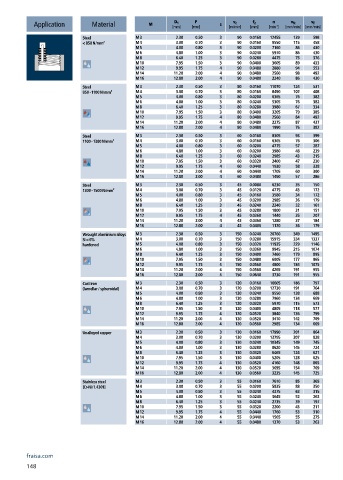

Application Material M [mm] [mm] z [m/min] [mm] [min ] -1 [mm/min] [mm/min]

Steel M 3 2.30 0.50 3 90 0.0160 12455 139 598

< 850 N/mm² M 4 3.00 0.70 3 90 0.0160 9550 115 458

M 5 4.00 0.80 3 90 0.0200 7160 86 430

M 6 4.80 1.00 3 90 0.0240 5970 86 430

M 8 6.40 1.25 3 90 0.0280 4475 75 376

M 10 7.95 1.50 3 90 0.0400 3605 89 433

M 12 9.95 1.75 4 90 0.0480 2880 94 553

M 14 11.20 2.00 4 90 0.0480 2560 98 492

M 16 12.80 2.00 4 90 0.0480 2240 86 430

Steel M 3 2.30 0.50 3 80 0.0160 11070 124 531

850 - 1100 N/mm² M 4 3.00 0.70 3 80 0.0160 8490 102 408

M 5 4.00 0.80 3 80 0.0200 6365 76 382

M 6 4.80 1.00 3 80 0.0240 5305 76 382

M 8 6.40 1.25 3 80 0.0280 3980 67 334

M 10 7.95 1.50 3 80 0.0400 3205 79 385

M 12 9.95 1.75 4 80 0.0480 2560 84 492

M 14 11.20 2.00 4 80 0.0480 2275 87 437

M 16 12.80 2.00 4 80 0.0480 1990 76 382

Steel M 3 2.30 0.50 3 60 0.0160 8305 93 399

1100 - 1300 N/mm² M 4 3.00 0.70 3 60 0.0160 6365 76 306

M 5 4.00 0.80 3 60 0.0200 4775 57 287

M 6 4.80 1.00 3 60 0.0200 3980 48 239

M 8 6.40 1.25 3 60 0.0240 2985 43 215

M 10 7.95 1.50 3 60 0.0320 2400 47 230

M 12 9.95 1.75 4 60 0.0440 1920 58 338

M 14 11.20 2.00 4 60 0.0440 1705 60 300

M 16 12.80 2.00 4 60 0.0480 1490 57 286

Steel M 3 2.30 0.50 3 45 0.0080 6230 35 150

1300 - 1500 N/mm² M 4 3.00 0.70 3 45 0.0120 4775 43 172

M 5 4.00 0.80 3 45 0.0160 3580 34 172

M 6 4.80 1.00 3 45 0.0200 2985 36 179

M 8 6.40 1.25 3 45 0.0240 2240 32 161

M 10 7.95 1.50 3 45 0.0280 1800 31 151

M 12 9.95 1.75 4 45 0.0360 1440 35 207

M 14 11.20 2.00 4 45 0.0360 1280 37 184

M 16 12.80 2.00 4 45 0.0400 1120 36 179

Wrought aluminium alloys M 3 2.30 0.50 3 150 0.0240 20760 349 1495

Si < 6% M 4 3.00 0.70 3 150 0.0280 15915 334 1337

hardened M 5 4.00 0.80 3 150 0.0320 11935 229 1146

M 6 4.80 1.00 3 150 0.0360 9945 215 1074

M 8 6.40 1.25 3 150 0.0400 7460 179 895

M 10 7.95 1.50 3 150 0.0480 6005 177 865

M 12 9.95 1.75 4 150 0.0560 4800 184 1075

M 14 11.20 2.00 4 150 0.0560 4265 191 955

M 16 12.80 2.00 4 150 0.0640 3730 191 955

Cast iron M 3 2.30 0.50 3 120 0.0160 16605 186 797

(lamellar / spheroidal) M 4 3.00 0.70 3 120 0.0200 12730 191 764

M 5 4.00 0.80 3 120 0.0240 9550 138 688

M 6 4.80 1.00 3 120 0.0280 7960 134 669

M 8 6.40 1.25 3 120 0.0320 5970 115 573

M 10 7.95 1.50 3 120 0.0400 4805 118 577

M 12 9.95 1.75 4 120 0.0520 3840 136 799

M 14 11.20 2.00 4 120 0.0520 3410 142 709

M 16 12.80 2.00 4 120 0.0560 2985 134 669

Unalloyed copper M 3 2.30 0.50 3 130 0.0160 17990 201 864

M 4 3.00 0.70 3 130 0.0200 13795 207 828

M 5 4.00 0.80 3 130 0.0240 10345 149 745

M 6 4.80 1.00 3 130 0.0280 8620 145 724

M 8 6.40 1.25 3 130 0.0320 6465 124 621

M 10 7.95 1.50 3 130 0.0400 5205 128 625

M 12 9.95 1.75 4 130 0.0520 4160 148 865

M 14 11.20 2.00 4 130 0.0520 3695 154 769

M 16 12.80 2.00 4 130 0.0560 3235 145 725

Stainless steel M 3 2.30 0.50 3 55 0.0160 7610 85 365

[Cr-Ni/1.4301] M 4 3.00 0.70 3 55 0.0200 5835 88 350

M 5 4.00 0.80 3 55 0.0240 4375 63 315

M 6 4.80 1.00 3 55 0.0240 3645 52 262

M 8 6.40 1.25 3 55 0.0240 2735 39 197

M 10 7.95 1.50 3 55 0.0320 2200 43 211

M 12 9.95 1.75 4 55 0.0440 1760 53 310

M 14 11.20 2.00 4 55 0.0440 1565 55 275

M 16 12.80 2.00 4 55 0.0480 1370 53 263

fraisa.com

148