Page 154 - Carbide drills I Thread cutting tools 2023

P. 154

f z

n

v c

v f

D 1

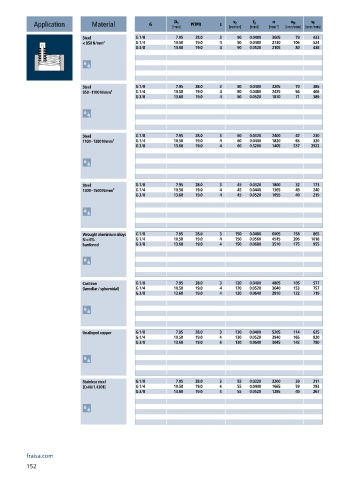

Application Material G [mm] P(TPI) z [m/min] [mm] [min ] -1 [mm/min] [mm/min]

v fc

Steel G 1/8 7.95 28.0 3 90 0.0400 3605 79 433

< 850 N/mm² G 1/4 10.50 19.0 4 90 0.0480 2730 106 524

G 3/8 13.60 19.0 4 90 0.0520 2105 80 438

Steel G 1/8 7.95 28.0 3 80 0.0400 3205 70 385

850 - 1100 N/mm² G 1/4 10.50 19.0 4 80 0.0480 2425 94 466

G 3/8 13.60 19.0 4 80 0.0520 1870 71 389

Steel G 1/8 7.95 28.0 3 60 0.0320 2400 42 230

1100 - 1300 N/mm² G 1/4 10.50 19.0 4 60 0.0440 1820 65 320

G 3/8 13.60 19.0 4 60 0.5200 1405 537 2922

Steel G 1/8 7.95 28.0 3 45 0.0320 1800 32 173

1300 - 1500 N/mm² G 1/4 10.50 19.0 4 45 0.0440 1365 49 240

G 3/8 13.60 19.0 4 45 0.0520 1055 40 219

Wrought aluminium alloys G 1/8 7.95 28.0 3 150 0.0480 6005 158 865

Si < 6% G 1/4 10.50 19.0 4 150 0.0560 4545 206 1018

hardened G 3/8 13.60 19.0 4 150 0.0680 3510 175 955

Cast iron G 1/8 7.95 28.0 3 120 0.0400 4805 105 577

(lamellar / spheroidal) G 1/4 10.50 19.0 4 120 0.0520 3640 153 757

G 3/8 13.60 19.0 4 120 0.0640 2810 132 719

Unalloyed copper G 1/8 7.95 28.0 3 130 0.0400 5205 114 625

G 1/4 10.50 19.0 4 130 0.0520 3940 165 820

G 3/8 13.60 19.0 4 130 0.0640 3045 143 780

Stainless steel G 1/8 7.95 28.0 3 55 0.0320 2200 39 211

[Cr-Ni/1.4301] G 1/4 10.50 19.0 4 55 0.0440 1665 59 293

G 3/8 13.60 19.0 4 55 0.0520 1285 49 267

fraisa.com

152