Page 158 - Carbide drills I Thread cutting tools 2023

P. 158

f z

v c

v f

n

D 1

v fc

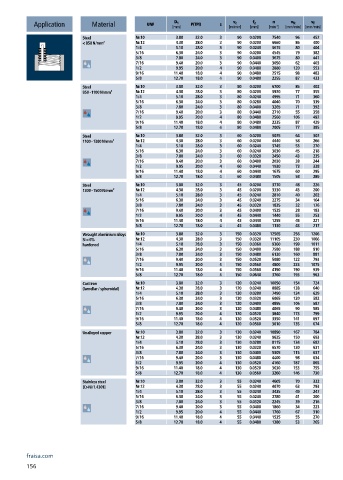

Application Material UNF [mm] P(TPI) z [m/min] [mm] [min ] -1 [mm/min] [mm/min]

Steel Nr.10 3.80 32.0 3 90 0.0200 7540 96 452

< 850 N/mm² Nr.12 4.30 28.0 3 90 0.0200 6660 86 400

1/4 5.10 28.0 3 90 0.0240 5615 80 404

5/16 6.30 24.0 3 90 0.0280 4545 79 382

3/8 7.80 24.0 3 90 0.0400 3675 80 441

7/16 9.40 20.0 3 90 0.0440 3050 62 403

1/2 9.95 20.0 4 90 0.0480 2880 120 553

9/16 11.40 18.0 4 90 0.0480 2515 98 483

5/8 12.70 18.0 4 90 0.0480 2255 87 433

Steel Nr.10 3.80 32.0 3 80 0.0200 6700 85 402

850 - 1100 N/mm² Nr.12 4.30 28.0 3 80 0.0200 5920 77 355

1/4 5.10 28.0 3 80 0.0240 4995 71 360

5/16 6.30 24.0 3 80 0.0280 4040 70 339

3/8 7.80 24.0 3 80 0.0400 3265 71 392

7/16 9.40 20.0 3 80 0.0440 2710 55 358

1/2 9.95 20.0 4 80 0.0480 2560 106 492

9/16 11.40 18.0 4 80 0.0480 2235 87 429

5/8 12.70 18.0 4 80 0.0480 2005 77 385

Steel Nr.10 3.80 32.0 3 60 0.0200 5025 64 302

1100 - 1300 N/mm² Nr.12 4.30 28.0 3 60 0.0200 4440 58 266

1/4 5.10 28.0 3 60 0.0240 3745 53 270

5/16 6.30 24.0 3 60 0.0240 3030 45 218

3/8 7.80 24.0 3 60 0.0320 2450 43 235

7/16 9.40 20.0 3 60 0.0400 2030 38 244

1/2 9.95 20.0 4 60 0.0440 1920 73 338

9/16 11.40 18.0 4 60 0.0440 1675 60 295

5/8 12.70 18.0 4 60 0.0480 1505 58 289

Steel Nr.10 3.80 32.0 3 45 0.0200 3770 48 226

1300 - 1500 N/mm² Nr.12 4.30 28.0 3 45 0.0200 3330 43 200

1/4 5.10 28.0 3 45 0.0240 2810 40 202

5/16 6.30 24.0 3 45 0.0240 2275 34 164

3/8 7.80 24.0 3 45 0.0320 1835 32 176

7/16 9.40 20.0 3 45 0.0400 1525 28 183

1/2 9.95 20.0 4 45 0.0440 1440 55 253

9/16 11.40 18.0 4 45 0.0440 1255 45 221

5/8 12.70 18.0 4 45 0.0480 1130 43 217

Wrought aluminium alloys Nr.10 3.80 32.0 3 150 0.0320 12565 256 1206

Si < 6% Nr.12 4.30 28.0 3 150 0.0320 11105 230 1066

hardened 1/4 5.10 28.0 3 150 0.0360 9360 199 1011

5/16 6.30 24.0 3 150 0.0400 7580 188 910

3/8 7.80 24.0 3 150 0.0480 6120 160 881

7/16 9.40 20.0 3 150 0.0520 5080 122 793

1/2 9.95 20.0 4 150 0.0560 4800 233 1075

9/16 11.40 18.0 4 150 0.0560 4190 190 939

5/8 12.70 18.0 4 150 0.0640 3760 193 963

Cast iron Nr.10 3.80 32.0 3 120 0.0240 10050 154 724

(lamellar / spheroidal) Nr.12 4.30 28.0 3 120 0.0240 8885 138 640

1/4 5.10 28.0 3 120 0.0280 7490 124 629

5/16 6.30 24.0 3 120 0.0320 6065 120 582

3/8 7.80 24.0 3 120 0.0400 4895 106 587

7/16 9.40 20.0 3 120 0.0480 4065 90 585

1/2 9.95 20.0 4 120 0.0520 3840 173 799

9/16 11.40 18.0 4 120 0.0520 3350 141 697

5/8 12.70 18.0 4 120 0.0560 3010 135 674

Unalloyed copper Nr.10 3.80 32.0 3 130 0.0240 10890 167 784

Nr.12 4.30 28.0 3 130 0.0240 9625 150 693

1/4 5.10 28.0 3 130 0.0280 8115 134 682

5/16 6.30 24.0 3 130 0.0320 6570 130 631

3/8 7.80 24.0 3 130 0.0400 5305 115 637

7/16 9.40 20.0 3 130 0.0480 4400 98 634

1/2 9.95 20.0 4 130 0.0520 4160 187 865

9/16 11.40 18.0 4 130 0.0520 3630 153 755

5/8 12.70 18.0 4 130 0.0560 3260 146 730

Stainless steel Nr.10 3.80 32.0 3 55 0.0240 4605 70 332

[Cr-Ni/1.4301] Nr.12 4.30 28.0 3 55 0.0240 4070 63 293

1/4 5.10 28.0 3 55 0.0240 3435 49 247

5/16 6.30 24.0 3 55 0.0240 2780 41 200

3/8 7.80 24.0 3 55 0.0320 2245 39 216

7/16 9.40 20.0 3 55 0.0400 1860 34 223

1/2 9.95 20.0 4 55 0.0440 1760 67 310

9/16 11.40 18.0 4 55 0.0440 1535 55 270

5/8 12.70 18.0 4 55 0.0480 1380 53 265

fraisa.com

156