Page 156 - Carbide drills I Thread cutting tools 2023

P. 156

f z

v c

v f

n

D 1

v fc

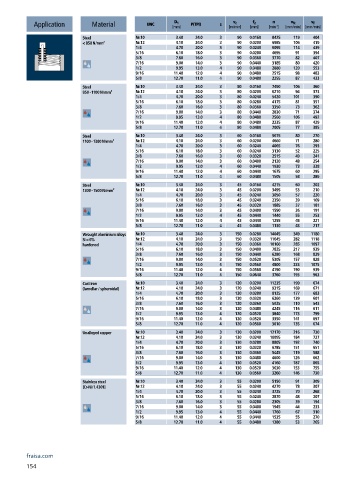

Application Material UNC [mm] P(TPI) z [m/min] [mm] [min ] -1 [mm/min] [mm/min]

Steel Nr.10 3.40 24.0 3 90 0.0160 8425 119 404

< 850 N/mm² Nr.12 4.10 24.0 3 90 0.0200 6985 106 419

1/4 4.70 20.0 3 90 0.0240 6095 114 439

5/16 6.10 18.0 3 90 0.0280 4695 91 394

3/8 7.60 16.0 3 90 0.0360 3770 82 407

7/16 9.00 14.0 3 90 0.0440 3185 80 420

1/2 9.95 13.0 4 90 0.0480 2880 120 553

9/16 11.40 12.0 4 90 0.0480 2515 98 483

5/8 12.70 11.0 4 90 0.0480 2255 87 433

Steel Nr.10 3.40 24.0 3 80 0.0160 7490 106 360

850 - 1100 N/mm² Nr.12 4.10 24.0 3 80 0.0200 6210 94 373

1/4 4.70 20.0 3 80 0.0240 5420 101 390

5/16 6.10 18.0 3 80 0.0280 4175 81 351

3/8 7.60 16.0 3 80 0.0360 3350 73 362

7/16 9.00 14.0 3 80 0.0440 2830 71 374

1/2 9.95 13.0 4 80 0.0480 2560 106 492

9/16 11.40 12.0 4 80 0.0480 2235 87 429

5/8 12.70 11.0 4 80 0.0480 2005 77 385

Steel Nr.10 3.40 24.0 3 60 0.0160 5615 80 270

1100 - 1300 N/mm² Nr.12 4.10 24.0 3 60 0.0200 4660 71 280

1/4 4.70 20.0 3 60 0.0240 4065 76 293

5/16 6.10 18.0 3 60 0.0240 3130 52 225

3/8 7.60 16.0 3 60 0.0320 2515 49 241

7/16 9.00 14.0 3 60 0.0400 2120 48 254

1/2 9.95 13.0 4 60 0.0440 1920 73 338

9/16 11.40 12.0 4 60 0.0440 1675 60 295

5/8 12.70 11.0 4 60 0.0480 1505 58 289

Steel Nr.10 3.40 24.0 3 45 0.0160 4215 60 202

1300 - 1500 N/mm² Nr.12 4.10 24.0 3 45 0.0200 3495 53 210

1/4 4.70 20.0 3 45 0.0240 3050 57 220

5/16 6.10 18.0 3 45 0.0240 2350 39 169

3/8 7.60 16.0 3 45 0.0320 1885 37 181

7/16 9.00 14.0 3 45 0.0400 1590 36 191

1/2 9.95 13.0 4 45 0.0440 1440 55 253

9/16 11.40 12.0 4 45 0.0440 1255 45 221

5/8 12.70 11.0 4 45 0.0480 1130 43 217

Wrought aluminium alloys Nr.10 3.40 24.0 3 150 0.0280 14045 349 1180

Si < 6% Nr.12 4.10 24.0 3 150 0.0320 11645 282 1118

hardened 1/4 4.70 20.0 3 150 0.0360 10160 285 1097

5/16 6.10 18.0 3 150 0.0400 7825 217 939

3/8 7.60 16.0 3 150 0.0440 6280 168 829

7/16 9.00 14.0 3 150 0.0520 5305 157 828

1/2 9.95 13.0 4 150 0.0560 4800 233 1075

9/16 11.40 12.0 4 150 0.0560 4190 190 939

5/8 12.70 11.0 4 150 0.0640 3760 193 963

Cast iron Nr.10 3.40 24.0 3 120 0.0200 11235 199 674

(lamellar / spheroidal) Nr.12 4.10 24.0 3 120 0.0240 9315 169 671

1/4 4.70 20.0 3 120 0.0280 8125 177 683

5/16 6.10 18.0 3 120 0.0320 6260 139 601

3/8 7.60 16.0 3 120 0.0360 5025 110 543

7/16 9.00 14.0 3 120 0.0480 4245 116 611

1/2 9.95 13.0 4 120 0.0520 3840 173 799

9/16 11.40 12.0 4 120 0.0520 3350 141 697

5/8 12.70 11.0 4 120 0.0560 3010 135 674

Unalloyed copper Nr.10 3.40 24.0 3 130 0.0200 12170 216 730

Nr.12 4.10 24.0 3 130 0.0240 10095 184 727

1/4 4.70 20.0 3 130 0.0280 8805 192 740

5/16 6.10 18.0 3 130 0.0320 6785 151 651

3/8 7.60 16.0 3 130 0.0360 5445 119 588

7/16 9.00 14.0 3 130 0.0480 4600 126 662

1/2 9.95 13.0 4 130 0.0520 4160 187 865

9/16 11.40 12.0 4 130 0.0520 3630 153 755

5/8 12.70 11.0 4 130 0.0560 3260 146 730

Stainless steel Nr.10 3.40 24.0 3 55 0.0200 5150 91 309

[Cr-Ni/1.4301] Nr.12 4.10 24.0 3 55 0.0240 4270 78 307

1/4 4.70 20.0 3 55 0.0240 3725 70 268

5/16 6.10 18.0 3 55 0.0240 2870 48 207

3/8 7.60 16.0 3 55 0.0280 2305 39 194

7/16 9.00 14.0 3 55 0.0400 1945 44 233

1/2 9.95 13.0 4 55 0.0440 1760 67 310

9/16 11.40 12.0 4 55 0.0440 1535 55 270

5/8 12.70 11.0 4 55 0.0480 1380 53 265

fraisa.com

154