Page 168 - Carbide drills I Thread cutting tools 2023

P. 168

v c

n

f z

v f

v fc

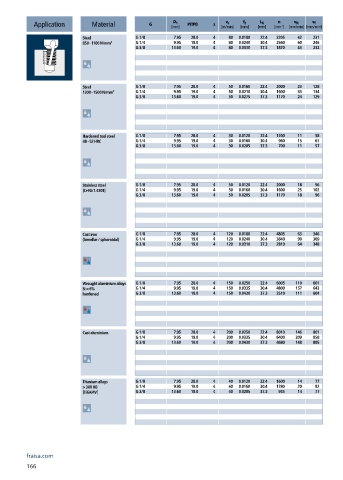

Application Material G [mm] P(TPI) z [m/min] [mm] [mm] [min ] [mm/min] [mm/min]

D 1

L K

-1

Steel G 1/8 7.95 28.0 4 80 0.0180 22.4 3205 42 231

850 - 1100 N/mm² G 1/4 9.95 19.0 4 80 0.0240 30.4 2560 60 246

G 3/8 13.60 19.0 4 80 0.0310 37.3 1870 43 232

Steel G 1/8 7.95 28.0 4 50 0.0160 22.4 2000 23 128

1300 - 1500 N/mm² G 1/4 9.95 19.0 4 50 0.0210 30.4 1600 33 134

G 3/8 13.60 19.0 4 50 0.0275 37.3 1170 24 129

Hardened tool steel G 1/8 7.95 28.0 4 30 0.0120 22.4 1200 11 58

48 - 52 HRC G 1/4 9.95 19.0 4 30 0.0160 30.4 960 15 61

G 3/8 13.60 19.0 4 30 0.0205 37.3 700 11 57

Stainless steel G 1/8 7.95 28.0 4 50 0.0120 22.4 2000 18 96

[Cr-Ni/1.4301] G 1/4 9.95 19.0 4 50 0.0160 30.4 1600 25 102

G 3/8 13.60 19.0 4 50 0.0205 37.3 1170 18 96

Cast iron G 1/8 7.95 28.0 4 120 0.0180 22.4 4805 63 346

(lamellar / spheroidal) G 1/4 9.95 19.0 4 120 0.0240 30.4 3840 90 369

G 3/8 13.60 19.0 4 120 0.0310 37.3 2810 64 348

Wrought aluminium alloys G 1/8 7.95 28.0 4 150 0.0250 22.4 6005 110 601

Si < 6% G 1/4 9.95 19.0 4 150 0.0335 30.4 4800 157 643

hardened G 3/8 13.60 19.0 4 150 0.0430 37.3 3510 111 604

Cast aluminium G 1/8 7.95 28.0 4 200 0.0250 22.4 8010 146 801

G 1/4 9.95 19.0 4 200 0.0335 30.4 6400 209 858

G 3/8 13.60 19.0 4 200 0.0430 37.3 4680 148 805

Titanium alloys G 1/8 7.95 28.0 4 40 0.0120 22.4 1600 14 77

> 300 HB G 1/4 9.95 19.0 4 40 0.0160 30.4 1280 20 82

[Ti6Al4V] G 3/8 13.60 19.0 4 40 0.0205 37.3 935 14 77

fraisa.com

166